We now have several exceptional workers customers good at marketing, QC, and working with types of troublesome trouble during the creation system for Emg1 Emg12, Emg13 Pump Mechanical Seal replacement, At present, corporation name has much more than 4000 kinds of products and gained very good status and big shares on current market domestic and abroad.

We now have several exceptional workers customers good at marketing, QC, and working with types of troublesome trouble during the creation system for eMG1 pump mechanical seal, mechanical pump mechanical seal, mechanical seal eMG1, Water Pump Shaft Seal, We attained ISO9001 which provides solid foundation for our further development. Persisting in “High quality, Prompt Delivery, Competitive Price”, we have established long-term cooperation with clients from both overseas and domestically and get new and old clients’ high comments. It is our great honor to meet your demands. We are sincerely expecting your attention.

Features

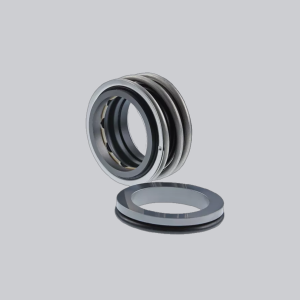

For plain shafts

Single and dual seal

Elastomer bellows rotating

Balanced

Independent of direction of rotation test

Advantages

- 100 % compatible with MG1

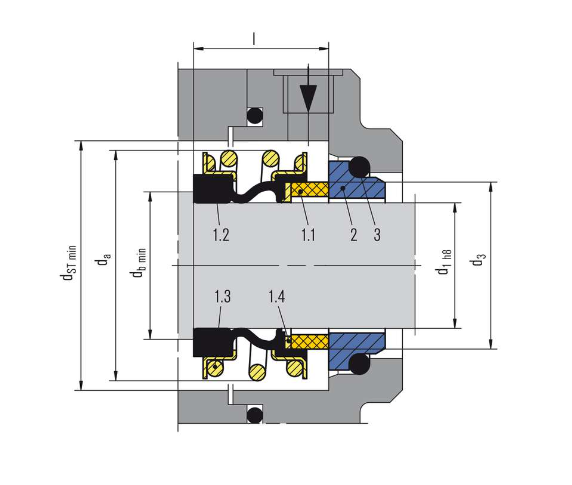

- Small outer diameter of bellows support (dbmin) enables direct retaining ring support, or smaller spacer rings

- Optimal alignment characteristic through self-cleaning of disk/shaft

- Improved centering across entire pressure operating range

- No torsion on bellows

- Shaft protection over entire seal length

- Protection of seal face during installation due to special bellows design

- Insensitive to shaft deflections due to large axial movement ability

- Suitable for low-end sterile applications

Recommended applications

- Fresh water supply

- Building services engineering

- Waste water technology

- Food technology

- Sugar production

- Pulp and paper industry

- Oil industry

- Petrochemical industry

- Chemical industry

- Water, waste water, slurries

(solids up to 5 % by weight) - Pulp (up to 4 % otro)

- Latex

- Dairies, beverages

- Sulfide slurries

- Chemicals

- Oils

- Chemical standard pumps

- Helical screw pumps

- Stock pumps

- Circulating pumps

- Submersible pumps

- Water and waste water pumps

s

Operating range

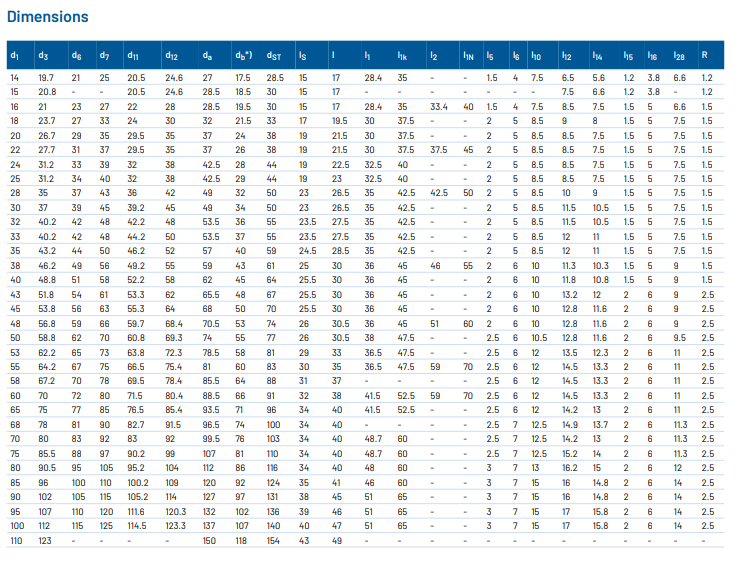

Shaft diameter:

d1 = 14 … 110 mm (0.55″ … 4.33″)

Pressure: p1 = 18 bar (261 PSI),

vacuum … 0.5 bar (7.25 PSI),

up to 1 bar (14.5 PSI) with seat locking

Temperature: t = -20 °C … +140 °C

(-4 °F … +284 °F)

Sliding velocity: vg = 10 m/s (33 ft/s)

Admissible axial movement: ±2.0 mm (±0.08″)

Combination material

Stationary Ring: Ceramic, Carbon, SIC, SSIC, TC

Rotary Ring: Ceramic, Carbon, SIC, SSIC, TC

Secondary Seal: NBR/EPDM/Viton

Spring and Metal Parts: SS304/SS316

WeMG1 data sheet of dimension(mm)

eMG1 pump shaft seal, mechanical pump seal