Power machines that have a rotating shaft, such as pumps and compressors, are generally known as “rotating machines.” Mechanical seals are a type of packing installed on the power transmitting shaft of a rotating machine. They are used in various applications ranging from automobiles, ships, rockets and industrial plant equipment, to residential devices.

Mechanical seals are intended to prevent the fluid (water or oil) used by a machine from leaking to the external environment (the atmosphere or a body of water). This role of mechanical seals contributes to the prevention of environmental contamination, energy saving through improved machine operating efficiency, and machine safety.

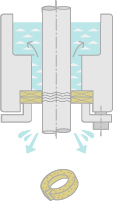

Shown below is a sectional view of a rotating machine that requires the installation of a mechanical seal. This machine has a large vessel and a rotating shaft at the center of the vessel (e.g., a mixer). The illustration shows the consequences of cases with and without a mechanical seal.

Cases with and without a mechanical seal

Without a seal

The liquid leaks.

With gland packing (stuffing)

The axis wears.

It needs some leaks (lubrication) to prevent wear.

With a mechanical seal

The axis does not wear.

There are hardly any leaks.

This control on liquid leakage is called “sealing” in the mechanical seal industry.

Without a seal

If no mechanical seal or gland packing is used, the liquid leaks through the clearance between the shaft and the machine body.

With a gland packing

If the aim is solely to prevent leakage from the machine, it is effective to use a seal material known as gland packing on the shaft. However, a gland packing tightly wound around the shaft hinders the motion of the shaft, resulting in shaft wear and therefore requiring a lubricant during use.

With a mechanical seal

Separate rings are installed on the shaft and on the machine housing to allow minimal leakage of the liquid used by the machine without affecting the rotating force of the shaft.

To ensure this, each part is fabricated according to a precise design. Mechanical seals prevent leakage even with hazardous substances that are difficult to mechanically handle or under harsh conditions of high pressure and high rotating speed.

Post time: Jun-30-2022