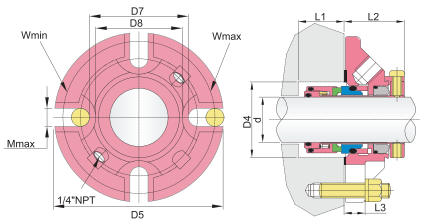

high quality cartridge mechanical seals replace AES CURC mechanical shaft seal,

Cartridge mechanical seals, cartridge pump seal, Pump Shaft Seal,

OPERATIONAL CONDITIONS:

TEMPERATURE: -20 ℃to +210 ℃

PRESSURE: ≦ 2.5MPa

SPEED: ≦15M/S

MATERIAL:

SATIONARY RING: CAR/ SIC/ TC

ROTARY RING: CAR/ SIC/ TC

SECONDARY SEAL: VITON/ EPDM/ AFLAS/ KALREZ

SPRING AND METAL PARTS: SS/ H-C

APPLICATIONS:

CLEAN WATER,

WEWAGE WATER,

OIL AND OTHER MODERATELY CORROSIVE FLUID.

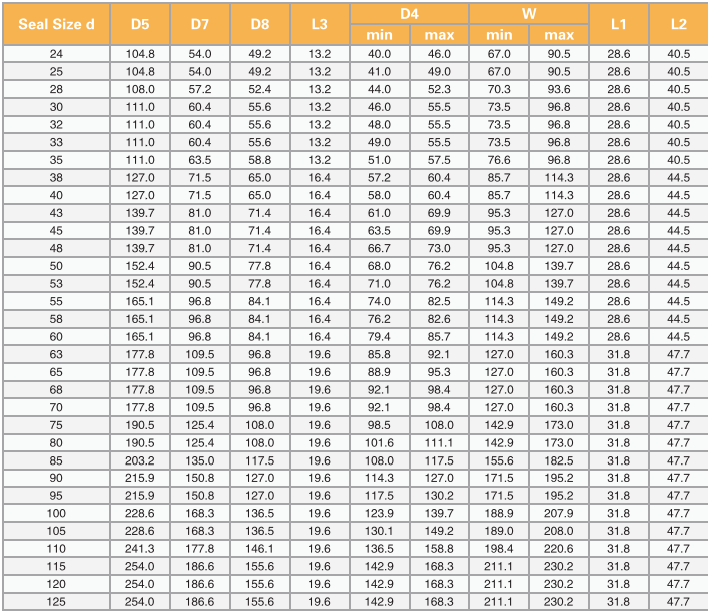

WCURC data sheet of dimension(mm)

Advantages of Cartridge Type Mechanical Seals

The major benefits of choosing cartridge seals for your pump seal system include:

- Easy / Simple installation (No specialist necessary)

- Higher functional security due to pre-assembled seal with fix axial settings. Eliminate measuring errors.

- Eliminated the possibility of axial misplacement and resulting seal performance issues

- Prevention of dirt entry or damaging of the seal faces

- Reduced installation costs through reduced installation time = Reduced down times during maintenance

- Potential to reduce the degree of pump disassembly for seal replacement

- Cartridge units are easily repairable

- Protection of customer shaft / shaft sleeve

- No need for custom made shafts to operate a balanced seal due to the internal shaft sleeve of the seal cartridge.