Sticking to your perception of “Creating solutions of top quality and making buddies with persons from all over the world”, we always set the desire of customers to start with for eMG1 rubber bellow mechanical seal for marine industry, We generally keep the philosophy of win-win, and develop long-term cooperation connection with buyers from around the planet.We feel that our expansion foundation on customer’s achievement, credit rating is our daily life.

Sticking to your perception of “Creating solutions of top quality and making buddies with persons from all over the world”, we always set the desire of customers to start with for , Insisting over the high-quality generation line management and prospects guide provider, we have made our resolution to offer our shoppers using the initially stage purchasing and soon after provider working experience. Preserving the prevailing helpful relations with our prospects, we even now innovate our product lists the many time to meet up with the brand new wants and stick to the latest trend of this business in Ahmedabad. We’re ready to facial area the difficulties and make the transform to grasp many of the possibilities in international trade.

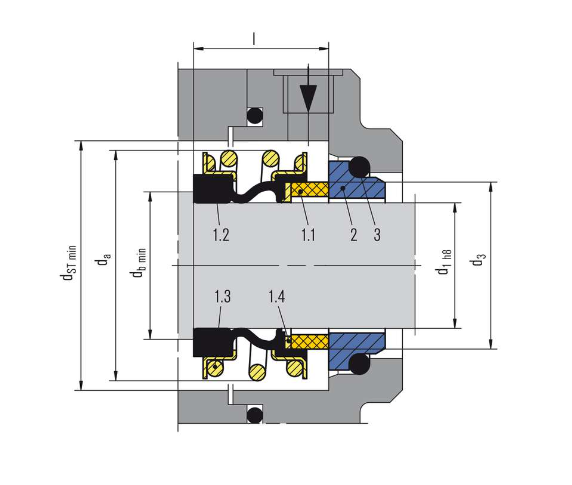

Features

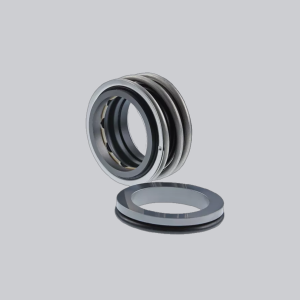

For plain shafts

Single and dual seal

Elastomer bellows rotating

Balanced

Independent of direction of rotation test

Advantages

- 100 % compatible with MG1

- Small outer diameter of bellows support (dbmin) enables direct retaining ring support, or smaller spacer rings

- Optimal alignment characteristic through self-cleaning of disk/shaft

- Improved centering across entire pressure operating range

- No torsion on bellows

- Shaft protection over entire seal length

- Protection of seal face during installation due to special bellows design

- Insensitive to shaft deflections due to large axial movement ability

- Suitable for low-end sterile applications

Recommended applications

- Fresh water supply

- Building services engineering

- Waste water technology

- Food technology

- Sugar production

- Pulp and paper industry

- Oil industry

- Petrochemical industry

- Chemical industry

- Water, waste water, slurries

(solids up to 5 % by weight) - Pulp (up to 4 % otro)

- Latex

- Dairies, beverages

- Sulfide slurries

- Chemicals

- Oils

- Chemical standard pumps

- Helical screw pumps

- Stock pumps

- Circulating pumps

- Submersible pumps

- Water and waste water pumps

s

Operating range

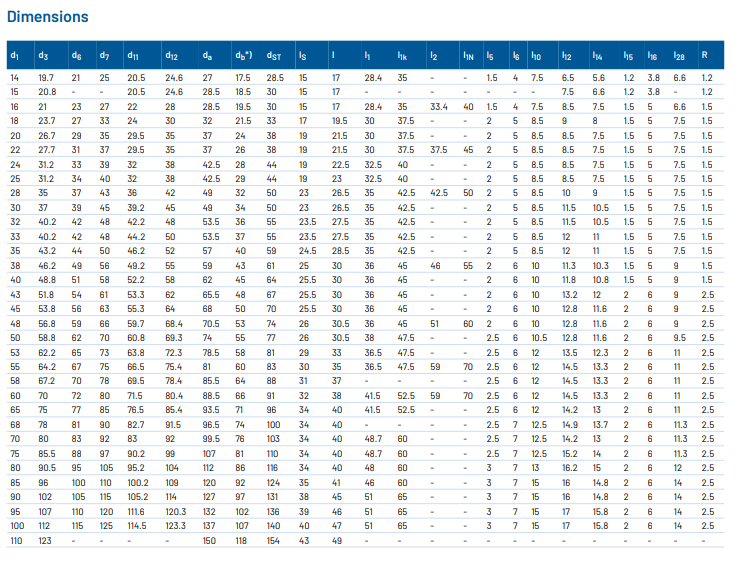

Shaft diameter:

d1 = 14 … 110 mm (0.55″ … 4.33″)

Pressure: p1 = 18 bar (261 PSI),

vacuum … 0.5 bar (7.25 PSI),

up to 1 bar (14.5 PSI) with seat locking

Temperature: t = -20 °C … +140 °C

(-4 °F … +284 °F)

Sliding velocity: vg = 10 m/s (33 ft/s)

Admissible axial movement: ±2.0 mm (±0.08″)

Combination material

Stationary Ring: Ceramic, Carbon, SIC, SSIC, TC

Rotary Ring: Ceramic, Carbon, SIC, SSIC, TC

Secondary Seal: NBR/EPDM/Viton

Spring and Metal Parts: SS304/SS316

WeMG1 data sheet of dimension(mm)

eMG1 rubber bellow mechanical seal, water pump shaft seal, mechanical pump seal