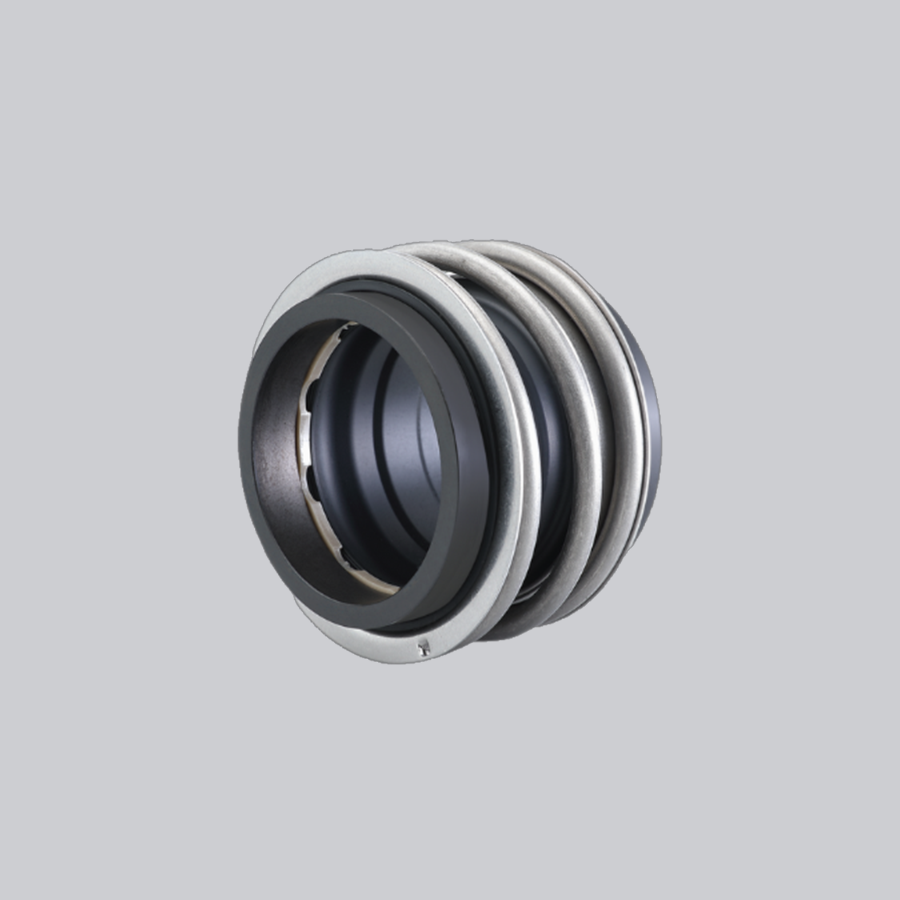

Our primary goal is always to offer you our customers a serious and responsible company relationship, providing personalized attention to all of them for eMG1 rubber bellow mechanical seal for marine industry, Our service concept is honesty, aggressive, realistic and innovation. Together with your assistance, we’ll mature much better.

Our primary goal is always to offer you our customers a serious and responsible company relationship, providing personalized attention to all of them for , Qualified R&D engineer might be there for your consultation service and we will try our best to meet your requirements. So remember to feel free to contact us for inquiries. You’ll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we will surely supply you with the best quotation and after-sale service. We’re ready to build stable and friendly relations with our merchants. To achieve mutual success, we’ll make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we’re here to welcome your inquiries for any of our items and service.

Features

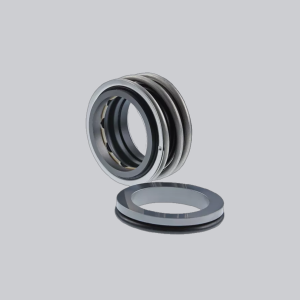

For plain shafts

Single and dual seal

Elastomer bellows rotating

Balanced

Independent of direction of rotation test

Advantages

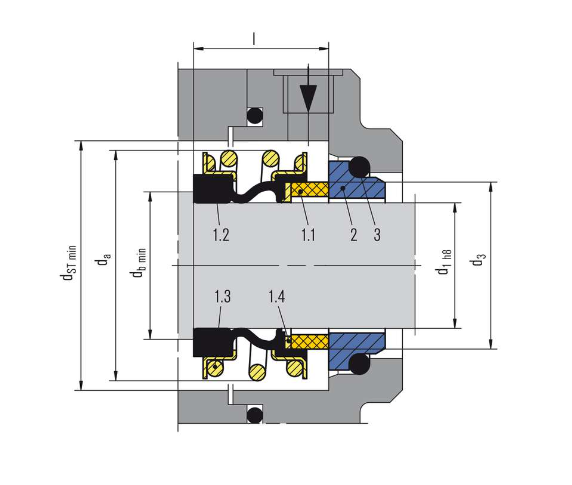

- 100 % compatible with MG1

- Small outer diameter of bellows support (dbmin) enables direct retaining ring support, or smaller spacer rings

- Optimal alignment characteristic through self-cleaning of disk/shaft

- Improved centering across entire pressure operating range

- No torsion on bellows

- Shaft protection over entire seal length

- Protection of seal face during installation due to special bellows design

- Insensitive to shaft deflections due to large axial movement ability

- Suitable for low-end sterile applications

Recommended applications

- Fresh water supply

- Building services engineering

- Waste water technology

- Food technology

- Sugar production

- Pulp and paper industry

- Oil industry

- Petrochemical industry

- Chemical industry

- Water, waste water, slurries

(solids up to 5 % by weight) - Pulp (up to 4 % otro)

- Latex

- Dairies, beverages

- Sulfide slurries

- Chemicals

- Oils

- Chemical standard pumps

- Helical screw pumps

- Stock pumps

- Circulating pumps

- Submersible pumps

- Water and waste water pumps

s

Operating range

Shaft diameter:

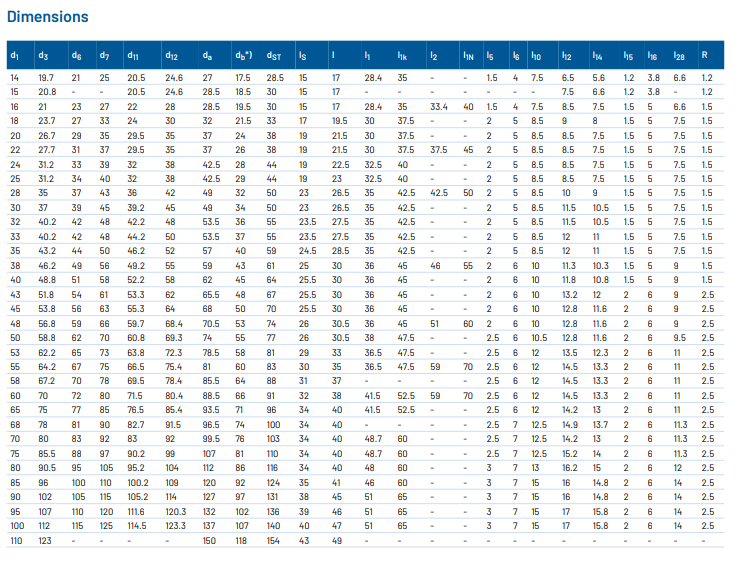

d1 = 14 … 110 mm (0.55″ … 4.33″)

Pressure: p1 = 18 bar (261 PSI),

vacuum … 0.5 bar (7.25 PSI),

up to 1 bar (14.5 PSI) with seat locking

Temperature: t = -20 °C … +140 °C

(-4 °F … +284 °F)

Sliding velocity: vg = 10 m/s (33 ft/s)

Admissible axial movement: ±2.0 mm (±0.08″)

Combination material

Stationary Ring: Ceramic, Carbon, SIC, SSIC, TC

Rotary Ring: Ceramic, Carbon, SIC, SSIC, TC

Secondary Seal: NBR/EPDM/Viton

Spring and Metal Parts: SS304/SS316

WeMG1 data sheet of dimension(mm)

pump shaft seal for marine industry