We’re proud from the higher client fulfillment and wide acceptance due to our persistent pursuit of high quality both on product and service for double mechanical seal for water pump M74D, And we could help seeking for just about any goods from the customers’ needs. Make sure present the best Company, the most effective High-quality, The fast Delivery.

We’re proud from the higher client fulfillment and wide acceptance due to our persistent pursuit of high quality both on product and service for M74D, Mechanical Shaft Seal, Pump And Seal, Pump Shaft Seal, water pump mechanical seal, To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of “innovation, harmony, team work and sharing, trails, pragmatic progress”. Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

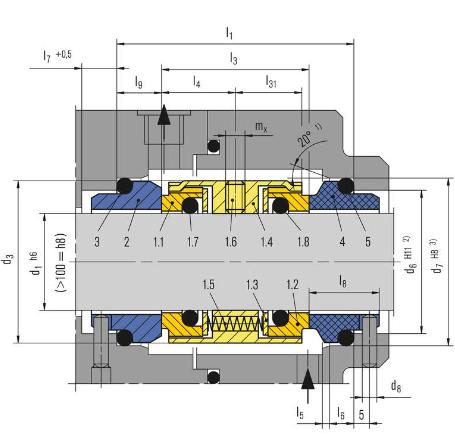

Features

•For plain shafts

•Dual seal

•Unbalanced

•Rotating multiple springs

•Independent of direction of rotation

•Seal concept based on the M7 range

Advantages

•Efficient stock keeping due to easily interchangeable faces

•Extended selection of materials

•Flexibility in torque transmissions

•EN 12756 (For connection dimensions d1 up to 100 mm (3.94″))

Recommended applications

•Chemical industry

•Process industry

•Pulp and paper industry

•Low solids content and low abrasive media

•Toxic and hazardous media

•Media with poor lubrication properties

•Adhesives

Operating range

Shaft diameter:

d1 = 18 … 200 mm (0.71″ … 7.87″)

Pressure:

p1 = 25 bar (363 PSI)

Temperature:

t = -50 °C … 220 °C

(-58 °F … 428 °F)

Sliding velocity:

vg = 20 m/s (66 ft/s)

Axial movement:

d1 up to 100 mm: ±0.5 mm

d1 from 100 mm: ±2.0 mm

Combination Materials

Stationary Ring (Carbon/SIC/TC)

Rotary Ring (SIC/TC/Carbon)

Secondary Seal (VITON/PTFE+VITON)

Spring & Other Parts (SS304/SS316)

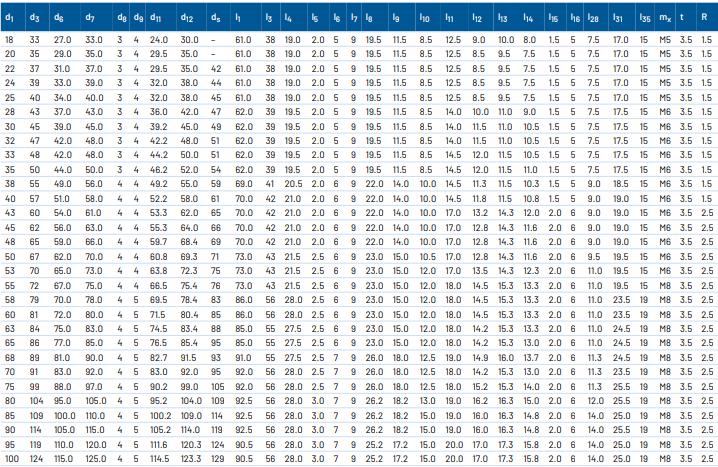

WM74D data sheet of dimension(mm)

Double face mechanical seals are designed to ensure that mechanical seals can work in a maximum sealing mode. Double face mechanical seals virtually remove leakage of the fluid or gas in pumps or mixers. Double mechanical seals provide a level of safety and minimize pump emission compliance not possible with single seals.It is essential to pump or mix a dangerous or toxic substance.

Double mechanical seals are mostly used in flammable, explosive, toxic, granular and lubricating medium. When it is used, it needs a sealing auxiliary system, that is, the isolation fluid is inserted in the sealing cavity between the two ends, thereby improving the lubrication and cooling conditions of the mechanical seal. The pump products that use double mechanical seal are: fluorine plastic centrifugal pump or IH stainless steel chemical pump, etc.

double face mechanical seal for water pump