We will constantly satisfy our respected customers with our good excellent, superior value and superior assistance due to we’re additional experienced and far more hard-working and do it in cost-effective way for Type 21 single spring mechanical seal for marine industry, We have ISO 9001 Certification and qualified this product or service .in excess of 16 years experiences in manufacturing and designing, so our goods featured with very best high-quality and aggressive rate. Welcome cooperation with us!

We will constantly satisfy our respected customers with our good excellent, superior value and superior assistance due to we’re additional experienced and far more hard-working and do it in cost-effective way for , The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer’s trust well.

Features

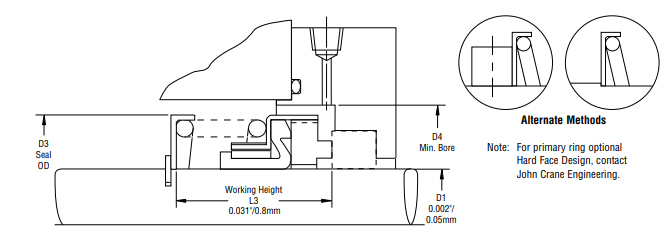

• The drive band’s “dent and groove” design eliminates overstressing of the elastomer bellows to prevent bellows slip and protect the shaft and sleeve from wear

• Non-clogging, single-coil spring provides greater dependability than multiple spring designs and will not foul due to fluid contact

• Flexible elastomer bellows automatically compensates for abnormal shaft-end play, run-out, primary ring wear and equipment tolerances

• Self-aligning unit automatically adjusts for shaft end play and run-out

• Eliminates potential shaft fretting damage between the seal and shaft

• Positive mechanical drive protects the elastomer bellows from overstressing

• Single coil spring improves tolerance to clogging

• Simple to fit and field repairable

• Can be used with practically any type of mating ring

Operation Ranges

• Temperature: -40˚F to 400°F/-40˚C to 205°C (depending on materials used)

• Pressure: up to 150 psi(g)/11 bar(g)

• Speed: up to 2500 fpm/13 m/ s (depending on configuration and shaft size)

• This versatile seal can be used on a wide range of equipment including centrifugal, rotary and turbine pumps, compressors, mixers, blenders, chillers, agitators, and other rotary shaft equipment

• Ideal for pulp and paper, pool and spa, water, food processing, wastewater treatment, and other general applications

Recommended Application

- Centrifugal Pumps

- Slurry Pumps

- Submersible Pumps

- Mixers & Agitators

- Compressors

- Autoclaves

- Pulpers

Combination Material

Rotary Face

Carbon graphite resin impregnated

Silicon carbide (RBSIC)

Hot-Pressing Carbon C

Stationary Seat

Aluminium oxide (Ceramic)

Silicon carbide (RBSIC)

Tungsten carbide

Auxiliary Seal

Nitrile-Butadiene-Rubber (NBR)

Fluorocarbon-Rubber (Viton)

Ethylene-Propylene-Diene (EPDM)

Spring

Stainless Steel (SUS304, SUS316)

Metal Parts

Stainless Steel (SUS304, SUS316)

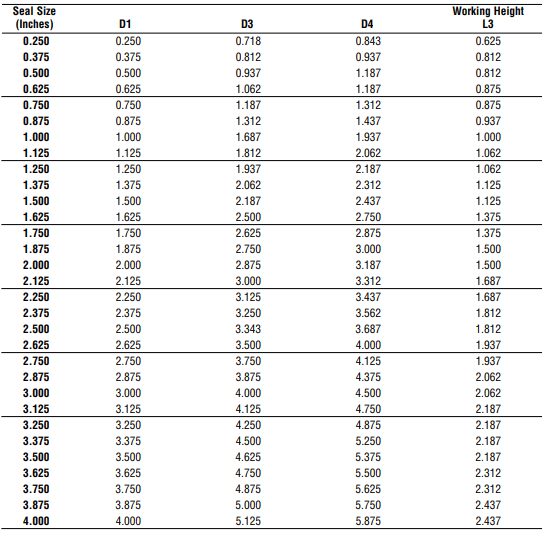

Type W21 DIMENSION DATA SHEET (INCHES)

Type 21 mechanical pump seal for marine industry

Type 21 mechanical pump seal for marine industry