Our business puts emphasis on the administration, the introduction of talented personnel, as well as the construction of team building, trying hard to further improve the standard and liability consciousness of staff members customers. Our enterprise successfully attained IS9001 Certification and European CE Certification of Type 21 single spring mechanical seal for marine industry, If you are interested in any of our products or would like to discuss a customized order, please feel free to contact us.

Our business puts emphasis on the administration, the introduction of talented personnel, as well as the construction of team building, trying hard to further improve the standard and liability consciousness of staff members customers. Our enterprise successfully attained IS9001 Certification and European CE Certification of , Our company sets up several departments, including production department, sales department, quality control department and sevice center,etc. only for accomplish the good-quality product to meet customer’s demand, all of our items have been strictly inspected before shipment. We always think about the question on the side of the customers,because you win,we win!

Features

• The drive band’s “dent and groove” design eliminates overstressing of the elastomer bellows to prevent bellows slip and protect the shaft and sleeve from wear

• Non-clogging, single-coil spring provides greater dependability than multiple spring designs and will not foul due to fluid contact

• Flexible elastomer bellows automatically compensates for abnormal shaft-end play, run-out, primary ring wear and equipment tolerances

• Self-aligning unit automatically adjusts for shaft end play and run-out

• Eliminates potential shaft fretting damage between the seal and shaft

• Positive mechanical drive protects the elastomer bellows from overstressing

• Single coil spring improves tolerance to clogging

• Simple to fit and field repairable

• Can be used with practically any type of mating ring

Operation Ranges

• Temperature: -40˚F to 400°F/-40˚C to 205°C (depending on materials used)

• Pressure: up to 150 psi(g)/11 bar(g)

• Speed: up to 2500 fpm/13 m/ s (depending on configuration and shaft size)

• This versatile seal can be used on a wide range of equipment including centrifugal, rotary and turbine pumps, compressors, mixers, blenders, chillers, agitators, and other rotary shaft equipment

• Ideal for pulp and paper, pool and spa, water, food processing, wastewater treatment, and other general applications

Recommended Application

- Centrifugal Pumps

- Slurry Pumps

- Submersible Pumps

- Mixers & Agitators

- Compressors

- Autoclaves

- Pulpers

Combination Material

Rotary Face

Carbon graphite resin impregnated

Silicon carbide (RBSIC)

Hot-Pressing Carbon C

Stationary Seat

Aluminium oxide (Ceramic)

Silicon carbide (RBSIC)

Tungsten carbide

Auxiliary Seal

Nitrile-Butadiene-Rubber (NBR)

Fluorocarbon-Rubber (Viton)

Ethylene-Propylene-Diene (EPDM)

Spring

Stainless Steel (SUS304, SUS316)

Metal Parts

Stainless Steel (SUS304, SUS316)

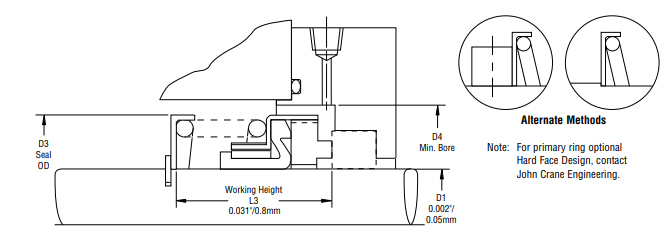

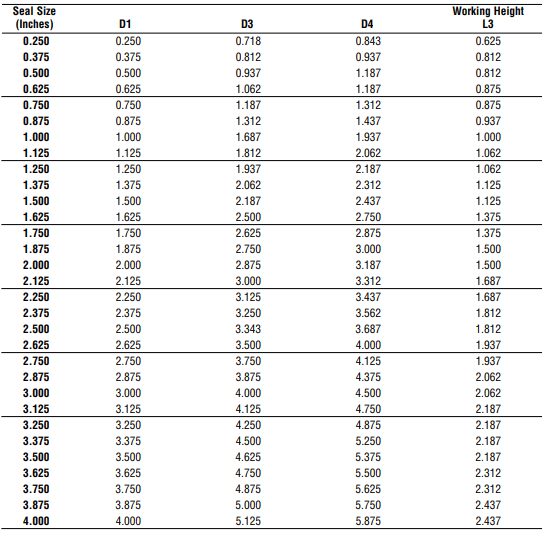

Type W21 DIMENSION DATA SHEET (INCHES)

mechanical pump seal for marine industry

mechanical pump seal for marine industry