While in the past few years, our organization absorbed and digested sophisticated technologies both equally at home and abroad. Meanwhile, our corporation staffs a group of experts devoted to your advancement of single spring and double mechanical seal for marine industry, Our corporation is dedicated to furnishing customers with high and steady top quality products at aggressive price tag, making just about every customer glad with our services and products.

While in the past few years, our organization absorbed and digested sophisticated technologies both equally at home and abroad. Meanwhile, our corporation staffs a group of experts devoted to your advancement of , We set a strict quality control system. We’ve got return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our solutions. Be sure to feel free to contact us for further information if you have any questions. We’ve been glad to work for every client.

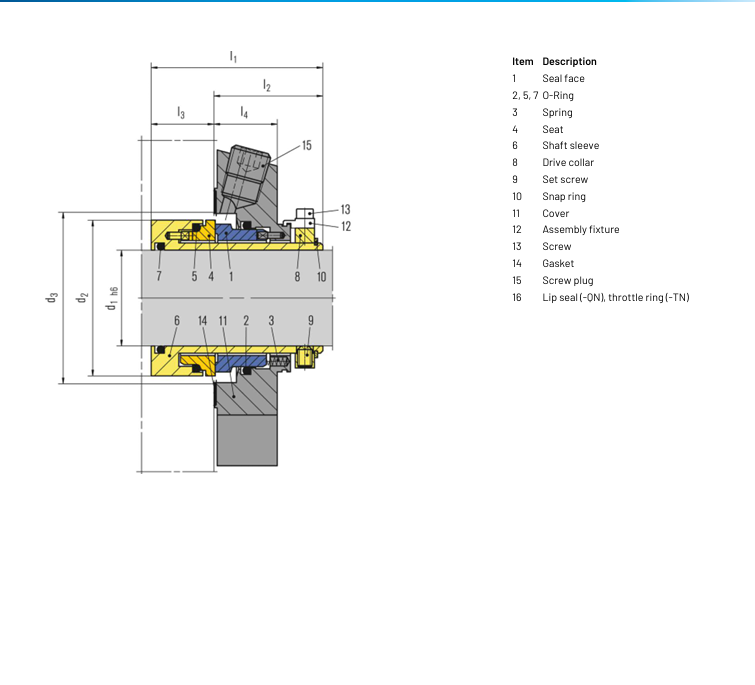

Features

- Single seal

- Cartridge

- Balanced

- Independent of direction of rotation

- Single seals without connections (-SNO), with flush (-SN) and with quench combined with lip seal (-QN) or throttle ring (-TN)

- Additional variants available for ANSI pumps (e.g. -ABPN) and eccentric screw pumps (-Vario)

Advantages

- Ideal seal for standardizations

- Universal applicable for packings conversions, retrofits or original equipment

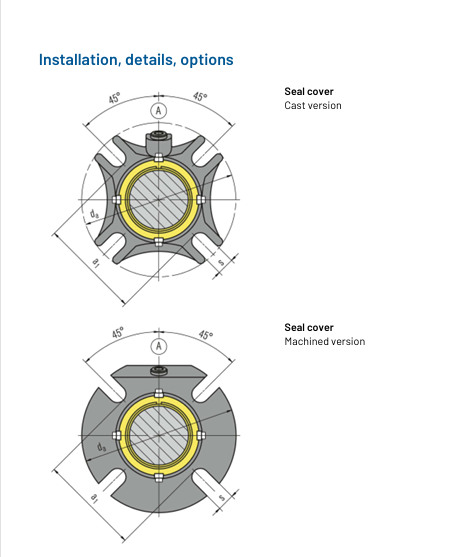

- No dimensional modification of the seal chamber (centrifugal pumps) necessary, small radial installation height

- No damage of the shaft by dynamically loaded O-Ring

- Extended service life

- Straightforward and easy installation due to pre-assembled unit

- Individual adaptation to pump design possible

- Customer specific versions available

Materials

Seal face: Silicon carbide (Q1), Carbon graphite resin impregnated (B), Tungsten carbide (U2)

Seat: Silicon carbide (Q1)

Secondary seals: FKM (V), EPDM (E), FFKM (K), Perflourocarbon rubber/PTFE (U1)

Springs: Hastelloy® C-4 (M)

Metal parts: CrNiMo steel (G), CrNiMo cast steel (G)

Recommended applications

- Process industry

- Petrochemical industry

- Chemical industry

- Pharmaceutical industry

- Power plant technology

- Pulp and paper industry

- Water and waste water technology

- Mining industry

- Food and beverage industry

- Sugar industry

- CCUS

- Lithium

- Hydrogen

- Sustainable plastics production

- Alternative fuels production

- Power generation

- Universally applicable

- Centrifugal pumps

- Eccentric screw pumps

- Process pumps

Operating range

Cartex-SN, -SNO, -QN, -TN, -Vario

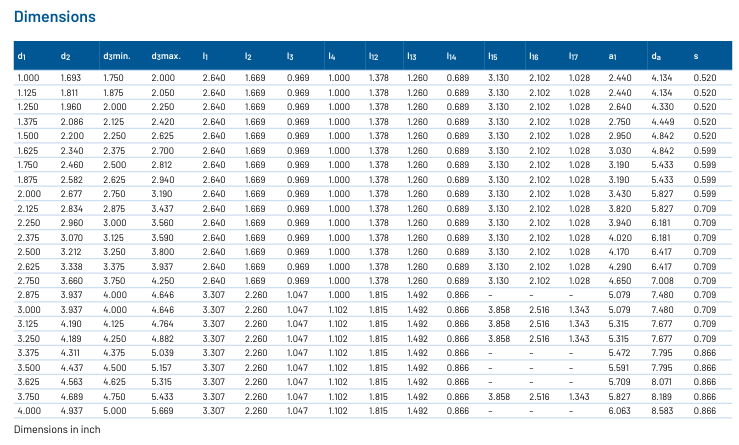

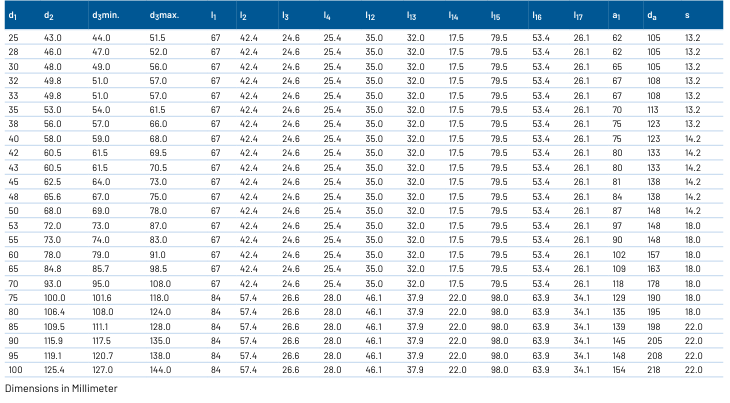

Shaft diameter:

d1 = 25 … 100 mm (1.000″ … 4.000″)

Other sizes on request

Temperature:

t = -40 °C … 220 °C (-40 °F … 428 °F)

(Check O-Ring resistance)

Sliding face material combination BQ1

Pressure: p1 = 25 bar (363 PSI)

Sliding velocity: vg = 16 m/s (52 ft/s)

Sliding face material combination

Q1Q1 or U2Q1

Pressure: p1 = 12 bar (174 PSI)

Sliding velocity: vg = 10 m/s (33 ft/s)

Axial movement:

±1.0 mm, d1 ≥75 mm ±1.5 mm

cartex mechanical seal for marine industry