It can be our accountability to satisfy your preferences and competently provide you. Your satisfaction is our greatest reward. We are searching ahead towards your visit for joint growth for single balanced cartridge mechanical seal for marine industry, We’ve been devoted to offer professional purification technology and methods in your case!

It can be our accountability to satisfy your preferences and competently provide you. Your satisfaction is our greatest reward. We are searching ahead towards your visit for joint growth for , If you have any requests, pls email Us with your detailed demands, we will offer you the most wholesale Competitive Price with the Super Quality and the Unbeatable First-class Service ! We can supply you with the most competitive prices and high quality, because we’re much more Specialist! So you should do not hesitate to contact us.

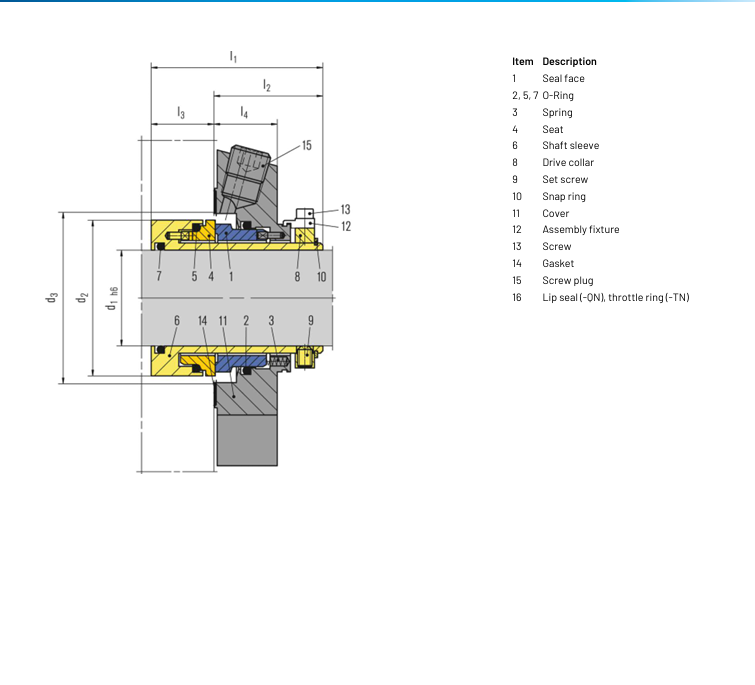

Features

- Single seal

- Cartridge

- Balanced

- Independent of direction of rotation

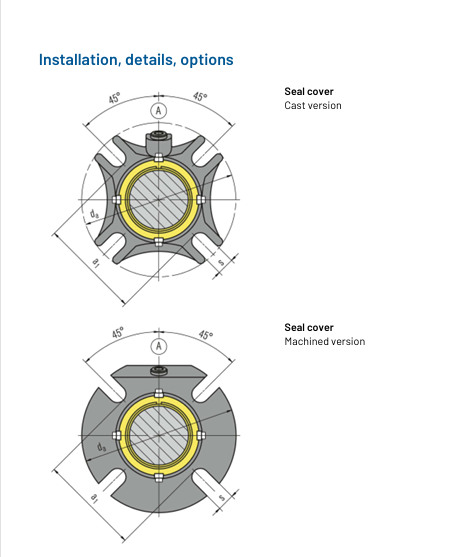

- Single seals without connections (-SNO), with flush (-SN) and with quench combined with lip seal (-QN) or throttle ring (-TN)

- Additional variants available for ANSI pumps (e.g. -ABPN) and eccentric screw pumps (-Vario)

Advantages

- Ideal seal for standardizations

- Universal applicable for packings conversions, retrofits or original equipment

- No dimensional modification of the seal chamber (centrifugal pumps) necessary, small radial installation height

- No damage of the shaft by dynamically loaded O-Ring

- Extended service life

- Straightforward and easy installation due to pre-assembled unit

- Individual adaptation to pump design possible

- Customer specific versions available

Materials

Seal face: Silicon carbide (Q1), Carbon graphite resin impregnated (B), Tungsten carbide (U2)

Seat: Silicon carbide (Q1)

Secondary seals: FKM (V), EPDM (E), FFKM (K), Perflourocarbon rubber/PTFE (U1)

Springs: Hastelloy® C-4 (M)

Metal parts: CrNiMo steel (G), CrNiMo cast steel (G)

Recommended applications

- Process industry

- Petrochemical industry

- Chemical industry

- Pharmaceutical industry

- Power plant technology

- Pulp and paper industry

- Water and waste water technology

- Mining industry

- Food and beverage industry

- Sugar industry

- CCUS

- Lithium

- Hydrogen

- Sustainable plastics production

- Alternative fuels production

- Power generation

- Universally applicable

- Centrifugal pumps

- Eccentric screw pumps

- Process pumps

Operating range

Cartex-SN, -SNO, -QN, -TN, -Vario

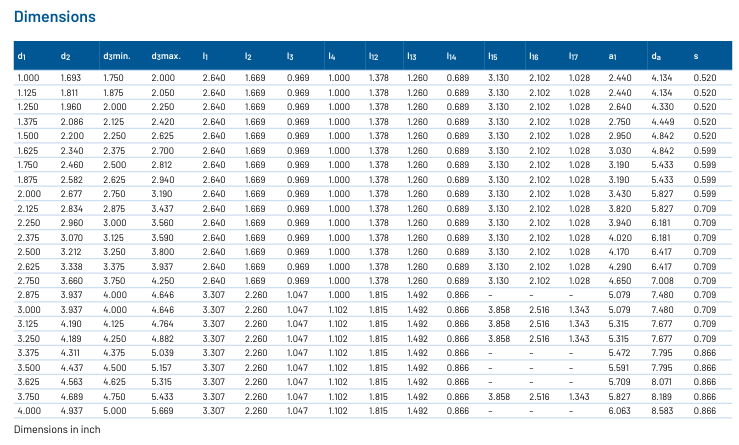

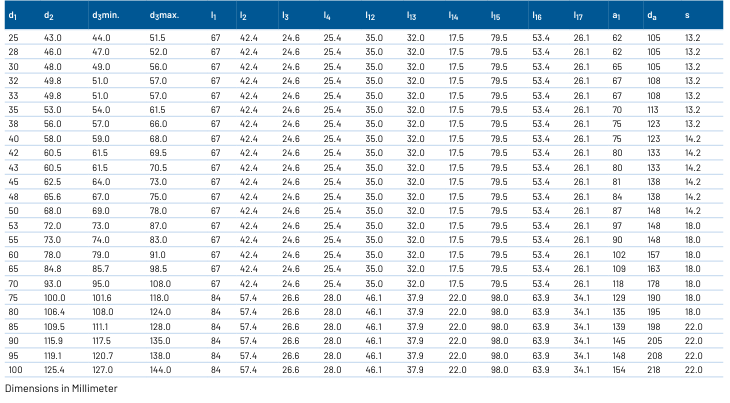

Shaft diameter:

d1 = 25 … 100 mm (1.000″ … 4.000″)

Other sizes on request

Temperature:

t = -40 °C … 220 °C (-40 °F … 428 °F)

(Check O-Ring resistance)

Sliding face material combination BQ1

Pressure: p1 = 25 bar (363 PSI)

Sliding velocity: vg = 16 m/s (52 ft/s)

Sliding face material combination

Q1Q1 or U2Q1

Pressure: p1 = 12 bar (174 PSI)

Sliding velocity: vg = 10 m/s (33 ft/s)

Axial movement:

±1.0 mm, d1 ≥75 mm ±1.5 mm

water pump shaft seal for marine industry

-

MFL85N metal bellow mechanical seal for marine ...

-

IMO pump mechanical seal for marine industry 19...

-

John crane Type 502 mechanical seals for water ...

-

O ring single spring mechanical seal Type 155 f...

-

Type E41 mechanical pump seal for marine industry

-

APV pump mechanical seal for marine industry fo...