Incompatible fluids cause immediate mechanical seal failure, leading to significant Mechanical Seal Leakage and costly system downtime. Fluid compatibility directly dictates a mechanical seal’s operational lifespan and reliability. For instance, selecting the correct O-ring material is crucial. Proper material selection for Mechanical Seals, such as using Silicon Carbide Seal Faces when appropriate, prevents premature wear and catastrophic failures. This is especially vital for chemical resistant mechanical seals for aggressive media.

Key Takeaways

- Fluid compatibility is very important for mechanical seals. It stops seals from breaking down and leaking.

- Incompatible fluids can cause many problems. These include material damage, corrosion, and early seal failure.

- Choosing the right materials for seals is key. This makes sure the seal works well and lasts a long time.

- Testing fluids and materials helps a lot. It makes sure seals can handle the job they need to do.

- Ignoring fluid compatibility costs money. It can also cause safety problems and harm the environment.

Understanding Fluid Compatibility for Mechanical Seals

Defining Chemical Compatibility

Chemical compatibility refers to a mechanical seal material’s ability to resist degradation when it contacts a specific fluid. This resistance is crucial for preventing seal failure. Several key chemical properties define this compatibility. These properties include the fluid’s operating temperature, its pH level, and the system pressure. The concentration of the chemical within the fluid also plays a significant role. For instance, a seal material might perform adequately with a diluted chemical solution. However, it could quickly fail when exposed to a highly concentrated version of the same chemical. Engineers must thoroughly assess these factors. This assessment helps prevent material breakdown, corrosion, or other forms of chemical attack that compromise seal integrity.

Physical Property Considerations

Beyond chemical reactions, a fluid’s physical properties significantly influence mechanical seal performance. Fluid viscosity and specific gravity are critical factors for seal operation. Low viscosity fluids, such as pure water, can lead to higher wear rates on seal faces. This occurs because they provide insufficient fluid film support, especially as the fluid temperature increases. This condition often creates challenges for Plan 54 systems. Conversely, adding glycols, such as ethylene glycol or propylene glycol, to water increases the mixture’s viscosity. This provides improved lubrication for seal faces, extending their operational life. High viscosity barrier fluids, however, necessitate the use of hard-on-hard face combinations, such as silicon carbide versus silicon carbide. This prevents blistering of carbon faces, which can occur with softer materials. Furthermore, low viscosity fluids like simple alcohols (methanol, ethanol, propanol) are generally unsuitable for maintaining a stable fluid film. They possess poor lubricating properties and high vapor pressures. This remains true despite their ability to stay liquid and maintain moderate viscosity at very low temperatures. Proper consideration of these physical properties ensures the longevity and reliable operation of Mechanical Seals.

Mechanisms of Mechanical Seal Failure from Incompatibility

Material Degradation and Corrosion

Chemical incompatibility often leads to material degradation and corrosion in Mechanical Seals. This occurs when seal materials, including seal faces and elastomers, cannot withstand the chemical composition, temperature, and pressure of the process fluid. This incompatibility causes chemical attack, which makes seal components swell, shrink, crack, or corrode. Such damage compromises the seal’s integrity and mechanical properties, ultimately causing leakage and a shorter service life. Coking is another form of material degradation. It results from the oxidation or chemical breakdown of the product, forming heavy residues on the seal components.

Several specific corrosion mechanisms can occur. Stress corrosion happens in metal materials under stress within a corrosive environment. This leads to selective corrosion grooves, local corrosion, and eventual cracking. Austenitic stainless steel and copper alloys are susceptible, for example, a 1Cr18Ni9Ti drive sleeve in ammonia water pumps. Abrasion involves material destruction from the alternating action of wear and corrosion. A corrosive medium accelerates chemical reactions on the seal’s contact surface, destroying the protective oxide layer and leading to further corrosion. Gap corrosion occurs in small gaps between metal or non-metallic components. Stagnant media in these gaps accelerate metal corrosion. This is visible between mechanical seal spring seats and shafts or compensation ring auxiliary seals and shafts, causing grooves or corrosion points.

Electrochemical corrosion involves different materials in an electrolyte solution. Varying inherent potentials create an electric coupling effect, promoting corrosion in one material while inhibiting it in another. This is common in mechanical seal friction pairs, such as copper and nickel-chromium steel in oxidizing media. Comprehensive corrosion involves uniform corrosion across the surface of parts in contact with the media. This results in weight reduction, loss of strength, and reduced hardness. An example is 1Cr18Ni9Ti stainless steel multi-springs in dilute sulfuric acid. Local corrosion shows etched spots or holes. The surface layer becomes loose and porous, easily peeling off and losing wear strength. This is a selective dissolution of a phase in multi-phase alloys or an element in single-phase solid solutions. Cobalt-based cemented carbide in high-temperature strong alkali and reaction sintered silicon carbide, where free silicon corrodes, are examples.

Swelling and Embrittlement of Elastomers

Incompatible fluids cause significant issues like swelling and embrittlement in elastomers, which are critical components of mechanical seals. For instance, NBR elastomers exposed to high-pressure hydrogen environments experience excessive hydrogen permeation. This leads to swelling, blistering, and rapid degradation of mechanical integrity, often resulting in RGD (Rapid Gas Decompression) failure and crack penetration. Traditional elastomers also suffer swelling and blistering due to hydrogen permeation and dissolution in similar high-pressure hydrogen conditions.

Other fluid types also pose risks to specific elastomers. EPDM, for example, swells and softens when it contacts petroleum products such as fuels, lubricating oils/greases, and vegetable or natural oils/fats. FKM/Viton elastomers face degradation from high-pH (alkaline) substances, particularly ammonia found in refrigeration compressor oils. This exposure causes premature compression set, surface cracking, and a loss of elasticity. Acetates, including acetic acid, peroxyacetic/peracetic acid, ethyl acetate, butyl acetate, and acetate salts, also cause significant problems for FKM/Viton. These fluids lead to swelling, softening, surface attack or cracking, loss of elasticity and memory, and early leakage. Similarly, acrylates like acrylic acid, poly(vinyl acrylate), methyl/ethyl/butyl acrylate, and methacrylates (e.g., methyl methacrylate) cause similar degradation in FKM/Viton, often necessitating the use of more resistant materials like PTFE or FFKM.

Chemical Attack and Dissolution

Chemical attack and dissolution represent severe forms of incompatibility. Aggressive fluids can directly react with the seal material, breaking down its molecular structure. This process weakens the material, making it brittle or soft. For example, strong acids or bases can dissolve certain polymers or metals used in seal construction. This chemical reaction removes material from the seal components, leading to thinning, pitting, or complete disintegration. The integrity of the seal face or secondary sealing elements diminishes rapidly under such conditions. This results in immediate leakage and catastrophic seal failure. The extent of chemical attack depends on the fluid’s concentration, temperature, and the duration of exposure. Even seemingly mild chemicals can cause significant damage over time if the seal material lacks proper resistance.

Abrasive Wear and Erosion

Abrasive wear is a common failure mode for Mechanical Seals. Hard particles in the process fluid rub against the seal faces. These particles act as abrasives. They cause the seal faces to wear more quickly. Fluids with high particulate content wear down seal faces. This also affects their alignment. Contamination of process fluid with abrasive particles accelerates seal wear. This leads to leakage through the primary sealing interface. Over time, abrasive particles in the fluid reduce sealing effectiveness. This wear mechanism intensifies in applications involving solid-laden or abrasive fluids.

Thermal Degradation of Seal Components

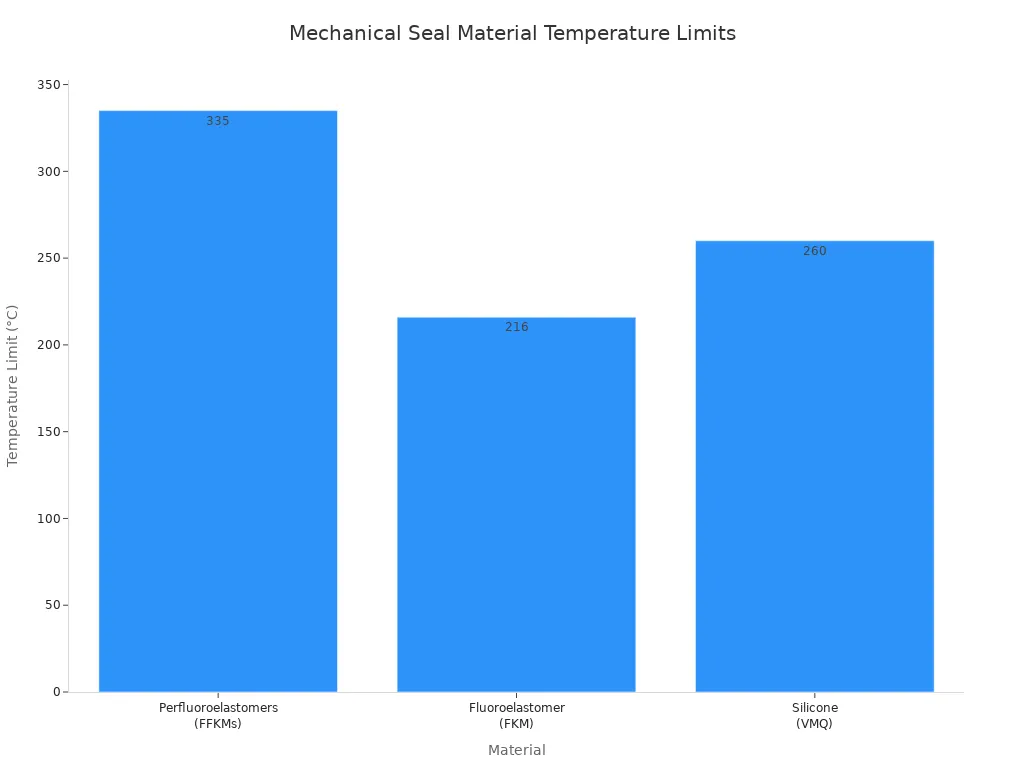

Thermal degradation happens when high temperatures damage seal materials. Incompatible fluids can operate at extreme temperatures. They can also cause exothermic reactions. These conditions push seal materials beyond their limits. Each seal material has a critical temperature limit. Exceeding this limit causes the material to lose its strength and integrity.

Consider these temperature limits for common seal materials:

| Material | Temperature Limit (°C) | Temperature Limit (°F) |

|---|---|---|

| Perfluoroelastomers (FFKMs) | 335 | 635 |

| Fluoroelastomer (FKM) | 200-232 | 392-450 |

| Silicone (VMQ) | 260 | 500 |

High-performance seals can generally withstand temperatures up to 316°C (600°F) or higher. Materials like graphite and silicon carbide are recognized for their thermal stability in high-temperature applications. When materials degrade thermally, they become brittle, soft, or even melt. This compromises the seal’s ability to prevent leaks.

Impact of Incompatible Fluids on Operational Efficiency

Increased Leakage and Product Loss

Incompatible fluids directly cause increased leakage from mechanical seals. When a seal material cannot withstand the fluid it contains, it loses its integrity. This leads to fluid escaping the system. Such leaks result in significant product loss, especially with valuable or hazardous chemicals. This not only wastes resources but also necessitates frequent refilling or replacement of the lost fluid. The continuous loss of product directly impacts a company’s bottom line.

Reduced Equipment Uptime and Productivity

Mechanical seal failure, often due to fluid incompatibility, significantly impacts overall equipment uptime and production output. Using an incorrect seal material not suited to operating conditions, such as temperature, pressure, or chemical exposure, can lead to rapid deterioration. Similarly, changing fluids without considering their compatibility with the seal material can cause chemical reactions. These reactions result in softening, swelling, cracking, or other forms of degradation. These issues compromise the seal’s ability to effectively contain fluids. This leads to system inefficiencies, increased maintenance costs, and downtime. For instance, a refinery can incur losses of $50,000 per hour due to downtime caused by a mechanical seal leak. In one specific case, a plant experienced a $100,000 loss in repairs and lost output due to a leak. This highlights the significant economic consequences of such failures.

Elevated Maintenance Costs for Mechanical Seals

Incompatible fluids lead to higher maintenance costs for Mechanical Seals. When seals fail prematurely due to chemical attack or degradation, they require more frequent replacement. This increases the demand for spare parts and labor. Technicians must spend more time diagnosing and repairing issues. Repeated failures also mean more emergency repairs, which are often more expensive than planned maintenance. These elevated costs directly reduce profitability and strain maintenance budgets.

Safety Hazards and Environmental Risks

Incompatible fluids pose significant safety hazards and environmental risks. Leaks from failed Mechanical Seals expose workers to toxic chemicals or harmful gases. This exposure can cause severe health complications, including skin and lung irritation, respiratory sensitization, and even carcinogenicity. Serious incidents, such as fires, explosions, hospitalizations, and loss of life, have occurred due to hazardous chemical releases. Beyond human health, industrial leaks lead to chemical spills or airborne toxins. These events cause long-term environmental damage, contaminating habitats and biodiversity. Examples like the Deepwater Horizon oil spill and the Bhopal gas tragedy highlight the potential for ecological disasters. Leaking petroleum products, for instance, contaminate soil and water sources, threatening wildlife and human health. Flammable fluids create immediate risks of fire and explosion. Even water leaks, while seemingly less severe, contribute to the strain on limited water resources and can cause physical injuries, structural damage, and corrosion. Proper seal installation helps industries minimize their environmental footprint and comply with stringent safety regulations.

Compromised System Performance and Reliability

Fluid incompatibility directly compromises overall system performance and reliability. Material incompatibility causes seal components to swell, corrode, or become brittle. Aggressive fluids chemically attack and corrode seal materials when engineers do not choose them correctly for the application. Choosing the wrong seal leads to premature failure, increased costs, and poses safety risks. Hostile operating conditions or changes in process parameters can override the seal’s design and material capabilities, thereby reducing its reliability. The application, process fluid, and environmental changes all contribute to the complex mix of factors impacting seal reliability. Misapplication of construction materials is a frequent error that quickly leads to premature seal failure. For example, sticky process fluids like glue or molasses can bind the seal faces together, compromising performance. This reduces the system’s efficiency and increases the likelihood of unplanned downtime, ultimately affecting the entire operational integrity.

Key Factors for Ensuring Mechanical Seal Compatibility

Comprehensive Fluid Analysis

Thorough fluid analysis forms the foundation for successful mechanical seal operation. Engineers must understand the process fluid’s characteristics to select compatible seal materials. This analysis includes several essential parameters. They examine the fluid’s reaction to temperature changes. Elevated temperatures can cause aqueous solutions to become poor lubricants. Light hydrocarbons may vaporize. Salts and caustics can precipitate. Oils might break down. Conversely, excessively cool temperatures lead to hardening and high viscosities. This increases shear forces and face damage.

Analysts account for every constituent of the fluid. They assess the nature of the fluid itself. The presence of solids in the pumped stream is critical. Corrosive contaminants, such as H2S or chlorides, require careful evaluation. If the product is a solution, its concentration matters. Engineers also determine whether the product solidifies under any encountered conditions.

Fluid viscosity is a primary consideration, especially at working temperature. It dictates the lubrication mode. Low viscosity services often require soft versus hard face combinations. Higher viscosity fluids allow for full fluid film lubrication. This potentially uses hard versus hard combinations to avoid issues like blistering in soft materials. Properties and concentrations of suspended solids or crystallization particles are also vital. In dirty or contaminated applications, particles harder than the face material can cause damage. This necessitates harder face materials. Fluids that crystallize or salt can also significantly damage soft faces. Material chemical compatibility is paramount. Seal faces are exposed to various process fluids. Some are aggressive and can chemically react with the material’s components. These include the base material, binder, or filler. Thermal considerations are also important. External factors (pumped fluid, heating/cooling jackets, piping plans) and internal factors (friction, turbulence) influence the seal face temperature. These can lead to thermal growth or retraction. They can also destroy impregnation or binding material. Thermal coning due to axial thermal gradients is another concern.

Material Selection Best Practices for Mechanical Seals

Selecting the correct materials is crucial for the longevity and performance of Mechanical Seals. Engineers must choose materials that resist the specific fluid’s chemical and physical properties. For highly corrosive applications, such as those involving strong acids or bases, specific material choices are necessary. Acid grade carbon graphite faces are available. These lack resin filler, making them suitable despite lower strength compared to other carbon graphite grades. However, direct sintered silicon carbide has largely replaced them. Silicon carbide is a common choice for hard faces. It offers high thermal conductivity, abrasion, and chemical resistance.

While reaction bonded silicon carbide has good wear properties, its 8-12% free silicon metal content limits chemical resistance. This makes it unsuitable for strong acids and bases (pH less than 4 or greater than 11). Direct sintered silicon carbide, also known as self-sintered silicon carbide, offers superior chemical resistance. It is almost entirely silicon carbide, without free silicon metal. This makes it resistant to most chemicals and suitable for nearly any mechanical seal application, including highly corrosive ones. Additionally, for highly corrosive services where no metal offers sufficient chemical compatibility or to avoid the high cost of premium metals, seal designs with no wetted metal components are available.

For specific highly corrosive fluids like hydrofluoric (HF) acid, engineers recommend particular material combinations. Seal faces require chemically-resistant carbon grades and alpha-sintered silicon carbide. Specific carbon grades must be evaluated for compatibility and durability due to the volatility and pressure of hydrofluoric acid. Perfluoroelastomers are the recommended secondary sealing element. Metal components, such as glands and collars, primarily use high alloy metals with superior corrosion resistance. Monel® Alloy 400 has historically been employed in many HF acid applications.

Consulting Mechanical Seal Manufacturers

Consulting mechanical seal manufacturers early in the design phase offers significant advantages for fluid compatibility assessments. This proactive approach enhances reliability. Early consultation helps anticipate failure points like material incompatibility. This leads to more robust designs. It also promotes cost efficiency. Addressing risks related to fluid compatibility early reduces lifecycle costs. This minimizes downtime and maintenance expenses.

Manufacturers can provide customized solutions. Tailored designs meet specific industry demands and fluid compatibility requirements. This mitigates associated risks. A “first-time-right” philosophy is achievable. A systematic approach ensures the initial design meets performance criteria. This reduces the need for costly iterations due to fluid compatibility issues.

Material selection directly influences a seal’s performance, reliability, and longevity. Early consultation ensures chosen materials are compatible with process fluids. They resist corrosion, erosion, and chemical attacks. This early assessment is vital for environments with abrasive, corrosive, or high-temperature fluids. It also helps consider how changes in fluid properties due to pressure and temperature might affect material integrity. This proactive approach, including the use of Failure Mode and Effects Analysis (FMEA), allows for the early identification and mitigation of potential failures related to material compatibility. This leads to enhanced reliability and cost efficiency.

Laboratory and Field Testing Protocols

Rigorous laboratory and field testing protocols are essential for validating mechanical seal material compatibility with process fluids. These tests ensure the chosen materials withstand the operational environment. The ASTM D471 Standard Test Method provides a structured approach. First, technicians prepare standardized test specimens. They measure initial dimensions, weight, and hardness, recording these as baseline properties. Next, they immerse samples in test oil at the maximum operating temperature. This immersion lasts for a standard duration, typically 70 hours minimum, with 168 hours preferred. They maintain the temperature within ±2°C. After immersion, technicians remove the samples, blot surface oil, and measure them within 30 minutes. They record volume change, weight change, and hardness change. Optional tests include tensile strength and elongation. Finally, they interpret the results. This involves calculating the volume swell percentage, assessing hardness change using a Shore A durometer, and evaluating the physical condition for cracking, softening, or tackiness.

A simplified field testing alternative also exists. This method requires 3-5 spare seals of each material, at least 500ml of actual compressor oil, a heat source with temperature control (oven or hot plate), glass containers with lids, calipers or a micrometer, and a Shore A hardness tester. The procedure involves measuring and recording initial seal dimensions and hardness. Then, technicians immerse the seals in heated oil for 168 hours (one week). After removal, they blot the seals dry and immediately measure dimensions and hardness. They calculate the percentage change. Acceptance criteria include a volume swell less than 10%, a hardness loss less than 10 Shore A, and no visible cracking, tackiness, or severe softening.

System Seals has developed new methods for material-fluid compatibility testing. These methods incorporate various standards and broad application experience. Their compatibility testing involves three main components: changes in basic mechanical properties, changes in thermal characteristics, and application-based performance. To ensure full fluid saturation and accelerate aging, specific time and temperature parameters are used. Water-mixed fluids, such as glycols or emulsions, are exposed to temperatures below 100°C. Oil-based fluids typically see temperatures above 100°C. Testing runs for 2,016 hours (12 weeks) to ensure full saturation. Base test parameters include volume swell, mass and density changes, hardness, tensile strength, elongation, 100 percent modulus, work function (area under tensile curve up to 20 percent), compression set, and abrasion resistance. Volume swell indicates fluid absorption; contraction is more problematic, reducing seal force. Other characteristics like volume, thickness, and density are monitored to assess dimensional changes from chemical aging. Mechanical property changes monitored include hardness, tensile modulus, 100-percent modulus, tensile strength, and elongation at break. The ultimate purpose is to evaluate an elastomer’s ability to function as a seal in its intended application when exposed to a working fluid. Application testing should be performed after core compatibility is established. This includes parameters to accelerate effects of pressure, temperature, surface finish, and motion (reciprocating, rotary, swivel).

Existing testing standards show considerable inconsistencies. ASTM D2000 typically uses a maximum exposure time of 70 hours, limiting long-term predictive capabilities. ASTM D4289, for automotive greases, recommends a limited number of property changes for evaluation. ASTM D6546 includes additional property evaluations, such as work function and compression set, but limits test duration to 1,000 hours. System Seals’ laboratory testing showed some fluid-material combinations compatible at 1,000 hours became incompatible after 2,000 hours. Many test recommendations lack established guidelines for static or dynamic applications. Most test standards do not incorporate changes in transition temperature, which is critical for low-temperature applications. This represents a significant gap in historic testing methods.

Assessing Operating Conditions (Temperature, Pressure, Speed)

Extreme operating temperatures and pressures significantly influence the selection of Mechanical Seals materials for fluid compatibility. High temperatures can degrade elastomeric components. For instance, ethylene propylene components degrade and leak beyond 300° Fahrenheit (150° C). High temperatures also cause some hydrocarbons to coke. This impedes the free movement of mechanical seal components. Process fluids can vaporize across seal faces, causing fugitive emissions. To address these challenges, material choices include elastomerics formulated for specific hydrocarbons, temperatures, and flush fluids. Seal faces are engineered for resilience and compatibility with process fluids. Examples include carbon, stainless, ceramic, tungsten, silicon, graphite, and nickel variants. Low-expansion alloys are used for metal seal components to minimize thermal expansion that jeopardizes seal performance. Inconel and Hastelloy are preferred for their exceptional thermal properties. They withstand extremes without compromising structural integrity. Inconel is superior in durability, withstanding temperatures exceeding 1,000°C. This makes it indispensable in aerospace and chemical processing industries. Temperature extremes compromise seal materials, leading to degradation or embrittlement. This diminishes mechanical properties and causes seal failure. Thermal cycling exacerbates this by inducing material fatigue.

Pressure variations necessitate seals with enhanced robustness. This prevents leakage in high-pressure environments. Mechanical face seals are often used for high-pressure systems. Spring-energized seals also help prevent leakage. Chemical compatibility remains crucial to prevent material degradation and environmental hazards. This ensures the seal does not suffer wear or breakdown from chemical exposure. Elastomers like Viton, EPDM, and Nitrile are chosen based on their resistance to specific chemicals and fluids. Viton is highly resistant to oils and fuels, ideal for automotive applications, and typically exhibits the longest lifespan in hydrocarbon exposure. EPDM resists water and steam, suitable for HVAC systems. Nitrile provides excellent abrasion resistance but can deteriorate when exposed to ozone. High operating speeds also generate heat, which further contributes to the thermal considerations for material selection.

Best Practices for Mechanical Seal Longevity

Regular Monitoring and Inspection

Regular monitoring and inspection are vital for extending the lifespan of Mechanical Seals. For critical applications, such as bellows seals, personnel conduct monthly visual inspections. They also perform quarterly performance assessments. Annual detailed examinations may include partial disassembly to evaluate internal components. Trained personnel visually inspect bellows surfaces for corrosion, fatigue cracking, dimensional distortion, or foreign material accumulation. Inspection ports and removable bonnets allow this without complete system disassembly. Performance monitoring tracks parameters like leakage rates, operating temperatures, vibration signatures, and actuator response times. This establishes baselines and identifies degradation trends. Advanced diagnostic techniques include borescopes for internal examination and thermal imaging equipment to detect temperature variations. Vibration analyzers, leak detection systems, ultrasonic thickness measurements, and eddy current testing also assess seal condition. Predictive maintenance involves real-time condition monitoring and data analysis. This anticipates maintenance needs and prevents unexpected downtime. Sensing and monitoring technologies, such as temperature, pressure, vibration, and leakage sensors, track abnormal operating conditions. Wireless sensors and remote monitoring systems enable real-time data collection and alerts. Statistical methods, trend monitoring, and predictive algorithms analyze this data. Computerized Maintenance Management Systems (CMMS) integrate data collection and analysis for managing maintenance schedules and historical data.

Proactive Maintenance Strategies

Implementing proactive maintenance strategies significantly extends mechanical seal lifespan. Regular inspection involves visual checks for wear, leaks, or damage. Personnel also examine seal face condition for scoring or pitting. Proper installation adheres to manufacturer guidelines. It uses appropriate tools for precise installation. Adequate lubrication for seal faces minimizes friction and wear. Proper cooling systems prevent overheating. Seal selection matches the seal to the application’s operating conditions. It ensures material compatibility with fluids and environmental factors. Operational monitoring tracks seal performance indicators like leakage rates and temperature. This adjusts operating parameters to prevent excessive wear. Contamination control maintains a clean environment around the seal. It uses filtration systems to remove particulates from the fluid. Avoiding dry running prevents seals from operating without continuous liquid between seal faces for cooling. Dry-run monitors can assist with this. Avoiding excessive vibration keeps pump systems within their Best Efficiency Point (BEP). This prevents recirculation and cavitation. Addressing system degradation or imbalance is also crucial. Correct lubrication uses the appropriate type of lubricant to maintain a cooling fluid film. This minimizes wear and friction. It also prevents temperature increases in seal chambers. Proper installation ensures correct and precise alignment and geometric accuracy. This prevents premature wear and failure.

Continuous Training for Personnel

Continuous training for personnel is essential for maintaining mechanical seal integrity and preventing compatibility issues. Training programs, such as the “Mechanical Seals – Construction and Design Webinar,” include the use of compatibility guides as a key topic. An expert, Gomez, emphasized the value of training in “compatibility of elastomers.” He recounted how it helped solve chronic seal failures at a refinery. He stated, “A few years ago, I did some training at a refinery, and just by teaching compatibility of elastomers I helped to solve some chronic seal failures. I strongly believe that training is the name of the game.” The “Industrial Seals” course (VS62XX) familiarizes students with the basics of various types of gaskets, packing, and seals. It covers “Types, Materials and Properties” of seals. This inherently includes aspects of fluid compatibility relevant to their application and performance.

Documenting Mechanical Seal Performance

Documenting mechanical seal performance provides crucial insights. This practice helps identify and address compatibility issues effectively. Comprehensive records allow teams to understand past behaviors and predict future problems. This proactive approach prevents unexpected failures and reduces costly downtime.

Teams should meticulously record various critical data points. They document actual operating parameters. These include flow rates, pressures, temperatures, and power consumption. Notations on deviations from design specifications are important. Such data reveals how the seal performs under real-world conditions. They also record process fluid properties. This includes temperature, viscosity, specific gravity, and chemical composition. Any changes from the original design or recent modifications are noted. This helps pinpoint fluid-related stress on the seal.

Furthermore, personnel document the system component condition. This covers piping, bearings, and support systems. They include any signs of wear or damage. This ensures the surrounding environment supports optimal seal function. Recording vibration levels is also essential. This involves historical and current vibration data, measurement locations, and frequency ranges. Identifying potential vibration sources helps prevent mechanical stress on the seal. Documenting equipment alignment conditions is another key step. Proper alignment minimizes undue stress on the seal faces.

Maintenance history provides valuable context. Teams collect and review maintenance records, work orders, and previous failure reports. This identifies recurring problems or component replacement patterns. They examine seal support systems. This includes flush systems, barrier fluid systems, and cooling circuits. Proper installation, operation, and calibration of instrumentation are verified. An environmental assessment records ambient operating temperatures, pressures, and fluid characteristics. Deviations from normal ranges are noted. Finally, teams document auxiliary systems. This covers cooling and lubrication systems, along with flush and barrier fluid systems. They ensure proper pressure, flow, and fluid quality.

Thorough documentation creates a valuable knowledge base. This information supports informed decision-making. It improves the reliability and longevity of these critical components. This practice ultimately contributes to overall operational efficiency and safety.

The Cost of Neglecting Mechanical Seal Compatibility

Financial Implications of Failure

Neglecting fluid compatibility for Mechanical Seals creates significant financial burdens for companies. Premature seal failures lead to increased expenses for replacement parts and labor. Organizations face higher maintenance costs due to frequent repairs and emergency interventions. Lost production time during unexpected shutdowns also results in substantial revenue losses. These direct and indirect costs severely impact a company’s profitability and operational budget.

Reputational Damage and Brand Impact

Fluid incompatibility can severely damage a company’s reputation and brand image. Product recalls, negative reviews, and a significant loss of consumer trust often follow incidents of compromised product integrity. Consumers expect safe, high-quality products. Any deviation from this expectation causes a decline in brand loyalty. For example, a survey revealed that 71% of pet owners would lose trust in their preferred pet food brand if it issued a recall. This highlights the critical importance of maintaining product integrity to preserve consumer confidence. Effective risk and failure analysis in mechanical seals is pivotal for operational excellence. This practice enhances product reliability, meets customer expectations, and reduces costs, thereby indirectly supporting brand image by ensuring product quality.

Regulatory Compliance Issues and Fines

Ignoring fluid compatibility also leads to serious regulatory compliance issues and substantial fines. Industries are subject to strict environmental regulations concerning emissions of pollutants, volatile organic compounds (VOCs), and hazardous materials. Failure to comply with these regulations can result in significant fines and legal consequences. California’s stringent environmental regulations, for instance, prohibit the leakage of toxic or hazardous fluids. Even negligible leakage in California can be problematic due to these regulations. Fugitive emissions can result in sanctions from regulatory bodies such as Cal/OSHA or BAAQMD. Environmental agencies often mandate specific sealing standards and practices to minimize environmental harm.

Fluid compatibility forms the cornerstone of reliable mechanical seal performance and system integrity. Prioritizing this compatibility prevents costly failures, ensures operational efficiency, and enhances safety. Proactive material selection, rigorous testing, and continuous monitoring are essential for long-term success with Mechanical Seals. These practices safeguard operations and optimize system reliability.

FAQ

What does fluid compatibility mean for mechanical seals?

Fluid compatibility describes a mechanical seal material’s ability to resist degradation when it contacts a specific fluid. This resistance prevents material breakdown, corrosion, or other chemical attacks. It ensures the seal maintains its integrity and functions reliably.

How do incompatible fluids cause mechanical seal failure?

Incompatible fluids cause seal failure through various mechanisms. They can degrade materials, leading to swelling or embrittlement of elastomers. Chemical attack and dissolution weaken components. Abrasive wear and erosion also occur. Thermal degradation of seal parts further contributes to failure.

Why is proper material selection crucial for mechanical seal compatibility?

Proper material selection is crucial because it directly impacts a seal’s operational lifespan. Choosing the correct materials ensures resistance to the fluid’s chemical and physical properties. This prevents premature wear, corrosion, and catastrophic failures. It also maintains seal integrity.

What are the main consequences of neglecting fluid compatibility?

Neglecting fluid compatibility leads to increased leakage and product loss. It reduces equipment uptime and productivity. Companies face elevated maintenance costs. It also creates safety hazards and environmental risks. Overall system performance and reliability become compromised.

Post time: Dec-30-2025