Highly reliable and quality-driven Chinese mechanical seal manufacturers for 2025 offer competitive solutions. They meet stringent international standards. These companies demonstrate significant advancements in Sealing Principle and design. This post reveals key players and their distinguishing factors. Manufacturers actively address common operational questions, such as “Why does my mechanical seal frequently overheat a” system. They also provide crucial insights on “How to differentiate the pros and cons of cartridg” designs. A prominent example is Victor Mechanical seal, known for its enduring quality and robust Bellows Seal offerings.

Key Takeaways

- Chinese mechanical seal makers offer good products. They use new technology and keep costs low. They also have many types of seals.

- Look for makers with quality certificates like ISO and API. They should also invest in new ideas and have good customer reviews.

- Chinese makers offer many seal types. These include cartridge, rubber, metal bellows, and O-ring seals. They can also make custom seals for special needs.

- To work well with Chinese makers, check them carefully. Talk clearly about what you need. Have strong contracts to ensure good quality.

Why Consider Chinese Mechanical Seal Manufacturers for Your Mechanical Seal Needs?

Advancements in Mechanical Seal Manufacturing Technology

Chinese manufacturers have significantly advanced their mechanical seal manufacturing technology. They now employ state-of-the-art machinery and automated production lines. This ensures high precision and consistency in every component. Investments in research and development drive innovation, leading to more durable and efficient sealing solutions. These technological leaps allow them to meet rigorous international performance standards.

Cost-Effectiveness Without Compromising Mechanical Seal Quality

Chinese mechanical seal manufacturers offer highly competitive pricing. This cost-effectiveness comes from efficient production processes, economies of scale, and optimized supply chains. They achieve these savings without compromising product quality. Strict quality control measures and adherence to international standards ensure that customers receive reliable and high-performing products. This balance of cost and quality makes them an attractive option for global industries.

Broad Mechanical Seal Product Range and Customization Capabilities

Chinese manufacturers provide an extensive range of mechanical seal products. They also excel in offering customized solutions. Many companies provide OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services. This indicates their high degree of flexibility in meeting specific industrial requirements. Customization options include:

- Modifications to dimensions, materials, and configurations

- Specialized face materials

- Balanced designs

- Multiple sealing points for hazardous applications

Manufacturers like Hongju Silicone, Lepu Seal, and Zhejiang Skylake Seals Manufacture Co., Ltd. offer custom solutions tailored to client needs. They emphasize research and development, providing OEM/ODM services. This demonstrates a strong commitment to diverse industrial requirements.

Key Criteria for Identifying Reliable Mechanical Seal Manufacturers

Certifications and Standards for Mechanical Seals (ISO, API, etc.)

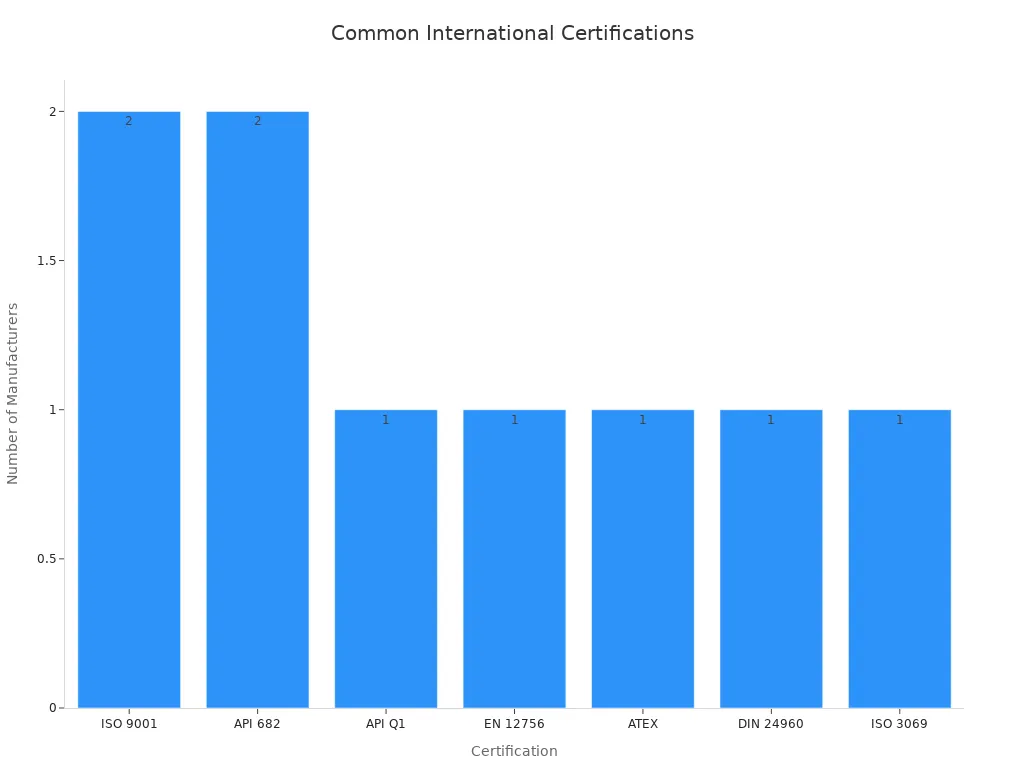

Reliable manufacturers demonstrate their commitment to quality through various certifications and adherence to international standards. These credentials assure buyers of consistent product quality, safety, and performance. Key certifications include ISO 9001, which signifies a robust quality management system, and API 682, specifically for centrifugal and rotary pumps. This standard ensures seals meet rigorous demands in the petroleum, petrochemical, and natural gas industries.

Manufacturers often hold multiple certifications, reflecting their comprehensive approach to quality. For example, leading Chinese manufacturers showcase impressive compliance:

| Manufacturer | Certifications/Compliance |

|---|---|

| FBU | LRQA ISO 9001:2015, API Q1 10th Edition, ISO 21049 (API 682), EN 12756, ATEX (selected products) |

| HQSeal | ISO9001 Quality Management System, DIN 24960, ISO 3069, API 682 |

These certifications are not just badges; they represent a manufacturer’s dedication to global best practices.

R&D Investment and Innovation in Mechanical Seal Design

A strong commitment to research and development (R&D) distinguishes forward-thinking manufacturers. Companies investing in R&D continuously improve their product lines and develop new solutions. This innovation leads to enhanced performance, greater durability, and increased efficiency in their sealing products. R&D efforts often focus on:

- Advanced Materials: Developing new materials for seal faces and secondary seals to withstand extreme temperatures, pressures, and corrosive media.

- Optimized Designs: Creating more efficient seal geometries and configurations for specific applications, reducing friction and energy consumption.

- Smart Sealing Solutions: Integrating sensors and monitoring capabilities for predictive maintenance and improved operational reliability.

Manufacturers who prioritize R&D stay ahead of industry trends. They offer cutting-edge solutions that meet the evolving demands of various industrial sectors.

Customer Testimonials and Case Studies for Mechanical Seals

Customer testimonials and detailed case studies offer invaluable insights into a manufacturer’s real-world performance. These accounts provide direct evidence of product reliability and customer satisfaction. They highlight how a manufacturer’s products solve specific challenges and deliver tangible benefits.

JSPSEAL emphasizes its reliability and performance through numerous case studies and customer testimonials. These examples demonstrate the company’s capability to provide effective sealing solutions for challenging applications. This solidifies its reputation as a trusted manufacturer in the hydraulic seals industry.

Consider these examples from Rock Metal, showcasing their problem-solving capabilities for mechanical seal applications:

- Mechanical Pump Seals: A customer tested Rock Metal’s mechanical seal. It significantly extended service life and improved leakage. This led to ongoing cooperation.

- Special Graphite for Air Compressor: Rock Metal developed a special graphite for a domestic customer’s air compressor. This increased the service life from 5 days to over 30 days for Freon medium.

- Metal Bellows Seals for Circulating Boiler Equipment: Rock Metal provided a solution for a customer’s circulating boiler equipment. They recommended a double-layer metal bellows seal and material changes. This resulted in good customer feedback since May 2023.

- Improvement of Multi-Spring Mechanical Seals and Packing: Rock Metal addressed issues with a long-term customer’s multi-spring mechanical seal (stuck by particles) and leaking packing. They recommended a wave spring and a widely used mechanical seal. This extended service life and improved leakage.

These real-world scenarios illustrate a manufacturer’s ability to deliver effective and durable sealing solutions.

After-Sales Support and Technical Assistance for Mechanical Seals

Comprehensive after-sales support and technical assistance form a critical component of a reliable mechanical seal manufacturer’s offering. This support ensures optimal performance and longevity for the seals. Manufacturers understand that their responsibility extends beyond the initial sale, providing crucial services that minimize downtime and operational costs for clients.

Leading Chinese mechanical seal manufacturers offer a range of services to international clients. They provide essential maintenance and servicing for their products. These manufacturers also conduct training sessions, equipping client personnel with the knowledge to handle and maintain seals effectively. Furthermore, they offer on-site services, directly addressing issues at the client’s facility. This robust technical support and after-sales service significantly minimize installation time and reduce plant maintenance costs.

Manufacturers go further with their support, offering specialized assistance. They perform on-site physical dimensioning of equipment, ensuring a perfect fit for custom seals. They also provide installation and running trial services, guaranteeing proper setup and initial operation. To support continuous operations, these companies offer inventory maintenance for mechanical seals and spare parts. Clients can also secure repair and maintenance contracts, even for third-party mechanical seals. Technical services include developing comprehensive mechanical sealing solutions. Manufacturers even perform reverse engineering of worn-out seals, providing replacements or improved designs. They offer troubleshooting and training on mechanical seals, empowering clients to resolve common issues independently.

This commitment to post-purchase care includes technology support and training services for mechanical seals. Manufacturers stand by their products with mechanical seal troubleshooting services. They also provide a quality guarantee, assuring customers of their product’s reliability and performance. This extensive support network ensures clients receive continuous value and operational efficiency from their mechanical seal investments.

Top Reliable Chinese Mechanical Seal Manufacturers for 2025

Ningbo Victor Seals Co., Ltd.: A Legacy in Mechanical Seal Manufacturing

Ningbo Victor Seals Co., Ltd. stands as a prominent manufacturer with a long operational history. Established in December 1984, the company has built a strong reputation. Its brand, “Victor,” is globally registered in over 30 countries, demonstrating international recognition. Victor Seals offers a comprehensive product range. This includes cartridge, rubber bellow, metal bellow, and O-ring type mechanical seals. They also provide spare parts made from various materials like Silicon Carbide, Tungsten Carbide, Ceramic, and Carbon.

The company adheres to strict international design standards. These include DIN24960, EN12756, ISO3069, API610, API682, and GB6556-94. Victor Seals’ products find applications across numerous industries. These sectors include petroleum, chemical, electric power, mechanicals, metallurgy, shipping, sewage treatment, printing and dyeing, food, pharmacy, and automotive. A team of professional engineers and technicians supports clients. They provide design, solution development, and on-site services. The technology department utilizes a PDM management system. This ensures efficient product development. Victor Seals continuously develops new mechanical seal types annually. This meets evolving market demands. Advanced production and testing equipment ensure product quality. The company holds ISO 9001:2000 quality system certification. It also possesses a Mechanical Seals Production License. Victor Seals emphasizes “Best Quality, Sincere Service.” It maintains strong customer relationships both domestically and internationally, serving clients in 30 overseas countries.

HQSeal: Custom Mechanical Seal Solutions and Auxiliary Systems

HQSeal distinguishes itself through its specialization in custom mechanical seal solutions and auxiliary systems. The company provides tailored sealing solutions for demanding industrial applications. HQSeal’s expertise extends to several critical sectors. They serve the aircraft industry, providing seals for high-performance needs. The company also offers solutions for chemical process pumps and slurry pumps, handling abrasive and corrosive media.

Furthermore, HQSeal specializes in seals for seawater pumps, addressing the challenges of marine environments. They also provide agitator seal pressure systems for various sensitive industries. These include the pharmaceutical, biotech, petrochemical, and chemical processing sectors. HQSeal’s focus on custom solutions ensures that clients receive precisely engineered products. These products meet their unique operational requirements.

Sealcon: Diverse Mechanical Seal Offerings and Sealing Solutions

Sealcon provides a diverse range of mechanical seal offerings and comprehensive sealing solutions. Their product portfolio includes various types of mechanical seals. These are Elastomer Rubber Bellow, Metal Bellow, PTFE Teflon Bellow, Single Cartridge, O Ring, Dual Cartridge, PTFE Wedge, Flygt, and O.E.M. Mechanical Seals. They also supply Stationary Seats.

Sealcon offers a wide array of seal spare parts. These include Sealing Rings, Springs, O-rings, Sleeves, and Glands. They also provide various mechanical sealing materials. These materials are Rubber, Stainless Steel, PTFE, Carbon, Ceramic, SiC, and TC Seals. Sealcon serves a broad spectrum of industries. These include Chemical, Oil and Gas, Pulp and Paper, Water Treatment, Food and Beverage, Marine Industry, Petrochemical Industry, and Pharmaceutical Industry. Beyond products, Sealcon offers valuable services. These services include Technical Help & Service, Technical Support, and Mechanical Seals Replacement.

Tianjin Zhonghuan Mechanical Seal Co., Ltd.: Industrial Hub Expertise

Tianjin Zhonghuan Mechanical Seal Co., Ltd. stands as a prominent manufacturer with a long history and a strong reputation within the domestic market. The company boasts a large production capacity, capable of meeting high demand for mechanical seals. They utilize a standardized production process to ensure consistency and quality. Their mechanical seals are highly compatible with domestic equipment, serving various industries like power, chemical, and steel.

Tianjin Zhonghuan Mechanical Seal Co., Ltd. specializes in Burgmann Mg12 mechanical seals. These seals achieve stable product quality through a strict quality management system and control over every production process. They find wide application in diverse industries, including power generation, metallurgy, and water treatment, adapting to different working conditions and media to provide reliable sealing solutions.

The company also demonstrates expertise in piston seals. Their piston seals offer stable sealing performance across varying pressures, temperatures, and fluid properties. They feature an anti-erosion design to resist solid particles and impurities, extending the seal’s lifespan. These seals also prioritize easy installation, reducing customer costs and time. Furthermore, Tianjin Zhonghuan Sealing Technology Co., Ltd. focuses on the development and production of high-performance cartridge seals. Their R&D team conducts in-depth research on sealing mechanisms and materials, enabling them to regularly introduce new and improved products. They serve diverse industries such as aerospace, defense, and high-tech manufacturing, ensuring strict quality and safety standards for their cartridge seals.

Lepu Seal: Two Decades of Mechanical Seal Experience

Lepu Seal brings over two decades of dedicated experience to the mechanical seal industry. This extensive history positions them as a seasoned and reliable manufacturer. Their long-standing presence in the market reflects a deep understanding of sealing technologies and industrial requirements. Over these twenty years, Lepu Seal has honed its manufacturing processes and product designs, consistently delivering solutions that meet demanding performance standards. Their accumulated expertise ensures customers receive durable and efficient mechanical seals, backed by years of practical application and continuous improvement.

YALAN Seals: Specialized Mechanical Seal Design and Production

YALAN Seals offers specialized mechanical seal design and production capabilities, backed by over 30 years of experience. The company holds 28 patents and numerous certifications, demonstrating its commitment to innovation and quality. YALAN Seals is a council member of HPSA (China Hydraulics Pneumatics & Seals Association) and has contributed to China National Standards for “Shaft Sealing Systems for Centrifugal and Rotary Pumps” (GB/T 34875-2017/ISO 21049:2004) and “Specification for Mechanical Seal of FGD Pump” (JB/T 12391-2015).

YALAN Seals operates an extensive production center in the Industrial Park of Dingyuan, Chuzhou, Anhui, China, spanning over 15,000 square meters. A new 50,000 square meter facility is currently under construction. This robust infrastructure supports 10 main production lines and 104 full-time employees, achieving an annual revenue of USD 13 million. The company boasts a broad product range, having designed and manufactured over 3,600 types of mechanical seals. Their design department is fully equipped to create custom mechanical seals tailored to specific client requirements. YALAN Seals also holds ISO9001:2015, ISO14001, and OHSAS18001 certifications, with inspections conducted by Bureau Veritas and SGS.

YALAN Seals provides a comprehensive array of specialized sealing solutions:

- Mixer & Agitator Seals: This category includes models like 2001, 2002, 2004, 2005, 2009, MK451, MK481, Type 202, 204, 204B, 205, 206, 207, 212, Flowserve Type RO, and HJCK for horizontal mixers.

- Slurry & FGD Seals: Designed for slurry pumps and FGD devices, with models such as ZGJ, ZHJ, ZWJ, TJL, HC80, B173, MN206, KTL, compatible with manufacturers like Kingda and Warman.

- Special Seals: Custom-designed for equipment including high-speed pumps, cryogenic pumps, immersion rolls, compressors, gearboxes, blowers, WILO pumps, and Flygt pumps.

- Spring Pusher Seals: Typical models include 58U, 59U, 58B, 59B, M3 series, Type 104, 105, 108U, M74, M7N, M524, Convertor II, SAI, Cartex SN, and DN.

- Bellow Seals: This includes metal and elastomer bellow mechanical seals, such as replacements for MG1, MG12, MG13, MG9, BIA, Type 21, 2100, Type 680, Type 609, and MFL85N.

- Paper & Pulp Seals: Replacement seals for Safematic series (SE1, SE2, SEW, SB2, JCS1, JCS2, TB1, TB2) and LP-D.

- Other Seals: A range of products including bearing isolators, mechanical seal support systems, spray coating shaft sleeves, friction pairs, O-rings, framework oil seals, and cylinder separators.

YALAN Seals’ products find versatile applications in various pumps (chemical, centrifugal, high-temperature oil, clean water, circulating, vacuum, sewage, slurry), reaction kettles, submerged motors, compressors, blowers, paper-making equipment, sewage treatment equipment, and other rotating machines.

Understanding Mechanical Seal Types and Applications from Chinese Manufacturers

Cartridge Mechanical Seals for Simplified Installation

Cartridge seals offer significant advantages for industrial equipment. They provide better reliability and performance, minimizing downtime and maximizing productivity in critical applications like oil and gas, chemical processing, and power generation. These seals simplify installation and service. Unlike conventional seals requiring precise alignment, cartridge seals arrive pre-assembled. This design allows for quick and easy installation, reducing system downtime and the chance of installation errors. Their modular design also facilitates easy maintenance and replacement without disassembling the entire pump. While initial costs might be higher, cartridge seals offer substantial long-term savings. This comes from lower maintenance requirements, a longer lifespan, and a reduced risk of leaks and failures. This prevents expensive repairs and production downtimes. They are also versatile across industries, adaptable for various applications, including harsh chemicals, extreme temperatures, or abrasive slurries. This makes them suitable for pumps, mixers, compressors, and agitators.

Rubber Bellow Mechanical Seals for Flexibility

Rubber bellow mechanical seals are highly valued for their inherent flexibility. This characteristic allows them to absorb unavoidable axial movements of the shaft or expansion of the sleeve due to temperature changes. This ensures the seal remains leak-free and maintains a tight seal over time, even with dynamic conditions. Industries commonly utilize these seals in pumps, especially centrifugal pumps, for handling liquids in sectors like oil and gas, chemical processing, and water treatment. They are also crucial for maintaining the integrity of compressor systems in refrigeration and air conditioning, preventing gas leakage. Furthermore, manufacturers employ them in agitators and mixers within pharmaceuticals, food and beverage, and chemical processing to prevent fluid leakage, withstanding dynamic movements and aggressive media.

Metal Bellow Mechanical Seals for High-Temperature Applications

Metal bellow mechanical seals excel in high-temperature applications where other seal types might fail. These seals are specifically designed to withstand extreme thermal conditions. For instance, standard configurations typically operate between -20℃ and +350℃. They can also handle significant pressures. The ORMG High-Temperature Metal Bellow Seals, for example, can withstand pressures up to 10 Bars. The MFL85N Metal Bellows Seals extend this capability, handling pressures up to 21 bar. Pressure capabilities often depend on the bellows design, with balanced configurations allowing for operation at higher pressures. This makes them ideal for demanding industrial environments.

O-Ring Mechanical Seals for Versatile Sealing

O-ring mechanical seals offer highly versatile sealing solutions across diverse industrial applications. Their design simplicity and effectiveness make them a popular choice for various equipment. The key to their adaptability lies in the wide array of materials available for the O-ring itself. Manufacturers carefully select these materials to ensure compatibility with different media, temperatures, and pressures.

For instance, Nitrile (Buna-N) provides good mechanical performance and resists water, basic oils, lubricants, and some fuels. However, it does not perform well with sunlight, ozone, or certain chemicals. Fluorocarbon (Viton®) offers excellent high-temperature capability and handles petroleum oils, silicone fluids, and acids, making it a versatile option. Conversely, it is not suitable for hot water or steam. Ethylene Propylene Rubber (EPR) shows good heat resistance and works well with steam, water, and silicone oils, but it resists petroleum oils poorly. Silicone excels in high-temperature static environments and offers strong ozone and UV resistance, though it lacks resistance to acids or brake fluids.

Here is a summary of common O-ring materials and their applications:

| Material | Key Properties & Versatility | Limitations | Common Applications |

|---|---|---|---|

| Nitrile (Buna-N) | Good mechanical performance, resists water, oils, lubricants | Poor resistance to ozone, sunlight, certain chemicals | General purpose, petroleum oils, water |

| Fluorocarbon (Viton®) | Excellent high-temperature, chemical, and oil resistance | Not for hot water/steam, amines, low molecular esters | Chemical processing, automotive fuel/oil |

| EPDM (Ethylene Propylene) | Good steam and chemical resistance (including ketones) | Not for petroleum oils and fuels | Life sciences, drinking water, food/medical grade |

| Silicone | High-temperature static environments, ozone/UV resistance | No resistance to acids, ketones, brake fluids | High-temperature static sealing, medical-grade |

This material diversity allows O-ring seals to provide reliable performance in numerous environments.

Custom Mechanical Seals for Unique Industrial Demands

Standard, off-the-shelf mechanical seals often cannot meet the specific requirements of certain industrial applications. Unique operational demands necessitate custom mechanical seal designs. These tailored solutions ensure optimal performance, reliability, and safety in challenging environments.

Industries frequently encounter extreme conditions that require specialized seals. These include high pressure, corrosive environments, or extreme temperatures. For example, the oil and gas sector needs specialized seals that withstand harsh chemicals and fluctuating pressures. Water and wastewater treatment facilities require seals that handle abrasive particles and corrosive fluids during 24/7 operations.

Other unique demands driving custom seal development include:

- Unique Equipment Specifications: Seals must be tailored to specific equipment, fluid properties, and operating conditions when off-the-shelf solutions are insufficient.

- Pharmaceutical and Food Processing: Stringent hygiene standards demand seals that resist contamination and are compatible with clean-in-place (CIP) processes, often requiring FDA-approved materials.

- Mining and Heavy Industries: Seals face harsh conditions, including abrasive slurries and extreme pressures, requiring robust designs and durable materials.

- Integration with Digital Maintenance Systems: The rise of Industry 4.0 necessitates smart seals with sensors for real-time monitoring and predictive maintenance.

Custom mechanical seals provide solutions for these complex challenges. They ensure equipment operates efficiently and safely under the most demanding circumstances.

Quality Control and Testing Protocols for Chinese Mechanical Seals

Chinese manufacturers implement rigorous quality control and testing protocols. These processes ensure their products meet high performance and reliability standards. They focus on every stage, from material selection to final product validation.

Material Selection and Traceability for Mechanical Seal Components

Manufacturers meticulously select materials for each component. They evaluate operating conditions, including temperature ranges, pressure requirements, and chemical compatibility. Professional seal manufacturers recommend optimal material combinations. For seal rings, they offer specific options like resin carbon, silicon carbide (SIC), and tungsten carbide. Elastomer selection considers chemical resistance and temperature, with choices such as FKM, EPDM, and NBR. Metal components, like SS304, SS316, and Hastelloy C, provide corrosion resistance and structural integrity. Manufacturers conduct thorough compatibility analyses. These analyses consider thermal expansion coefficients, galvanic corrosion potential, and chemical degradation rates. They also review historical performance data from similar applications.

Comprehensive quality management systems encompass material certification. Quality control processes include incoming material inspection, in-process monitoring, and final product testing. Manufacturing standards for custom seals include material traceability. Process documentation and quality certification procedures are standard practice. Manufacturers maintain certifications like ISO quality management systems, industry-specific standards, and customer-specific requirements.

Precision Manufacturing and Assembly of Mechanical Seals

Precision manufacturing and assembly are crucial steps. Manufacturers use advanced machinery and skilled technicians. This ensures tight tolerances and consistent product quality. Each component undergoes careful inspection before assembly. Automated processes and strict guidelines minimize human error. This meticulous approach guarantees the seals perform as designed.

Performance Testing and Validation of Mechanical Seals

Manufacturers conduct extensive performance testing and validation. This ensures seals meet operational demands. For O-ring seals, they perform various tests. A pressure test subjects the seal to increasing pressure levels. This assesses its ability to maintain a tight seal and determines maximum pressure resistance. A temperature test exposes the seal to extreme high and low temperatures. This evaluates its performance and resistance to material degradation under thermal stress. Mechanical stress testing evaluates the seal’s resilience against physical forces like vibration, shock, and torsion. This ensures integrity and sealing properties under mechanical stresses.

Validation processes include the qualification of materials and designs. This assesses materials, design, and manufacturing processes against required specifications. Performance validation tests seals under real-world operating conditions. This confirms their performance and reliability. Certification and compliance testing ensures seals meet industry standards and regulations. This often involves obtaining certifications from regulatory bodies.

Adherence to International Quality Standards for Mechanical Seals

Chinese mechanical seal manufacturers consistently adhere to stringent international quality standards. This commitment ensures their products meet global benchmarks for performance and reliability. Manufacturers understand the importance of these standards for market acceptance and customer trust. They implement robust quality management systems throughout their operations.

Many leading Chinese manufacturers comply with widely recognized international standards. These include ISO, DIN, and API. ISO (International Organization for Standardization) certifications, like ISO 9001, demonstrate a manufacturer’s dedication to quality management. DIN (Deutsches Institut für Normung) standards, originating from Germany, provide specific technical guidelines for various components. API (American Petroleum Institute) standards, particularly API 682, are crucial for seals used in the demanding oil and gas industry. Adhering to these standards means manufacturers produce seals that perform reliably in diverse industrial applications.

This strict adherence to international standards offers significant benefits to customers. It guarantees consistent product quality. Customers receive seals that meet specified performance criteria. It also ensures product compatibility with existing equipment and systems. This reduces risks associated with seal failure. Furthermore, compliance with these global benchmarks facilitates easier integration into international supply chains. This allows businesses worldwide to confidently source high-quality mechanical seals from China. Manufacturers’ commitment to these standards underscores their capability to deliver world-class sealing solutions.

How to Partner with a Chinese Mechanical Seal Manufacturer Successfully

Due Diligence and Verification of Mechanical Seal Suppliers

Successful partnerships begin with thorough due diligence. Businesses must carefully vet potential Chinese suppliers. This process involves several key steps. First, conduct initial research to create a shortlist. Use trade shows, B2B marketplaces, and industry contacts to identify suppliers meeting basic criteria. Next, perform a pre-audit assessment. Send questionnaires to gather data on business licenses, ISO certifications, and quality control processes. Engage in direct communication to evaluate their responsiveness and technical expertise. Finally, plan and conduct an on-site factory audit. This comprehensive inspection covers facilities, production processes, quality control systems, and compliance with safety and environmental regulations. Verify legal status, ownership, and certifications like ISO. Assess production capacity to ensure they can meet order quantities without compromising quality. Watch for red flags such as inconsistent information or reluctance to provide documentation.

Clear Communication and Specifications for Mechanical Seal Orders

Clear communication is paramount when working with Chinese manufacturers. Geographical and cultural distances make establishing effective channels crucial. Utilize project management tools and messaging apps for real-time updates and queries. Clearly articulate all specifications, expectations, and timelines. Define detailed quality standards, including materials, dimensions, and tolerances. This documentation serves as a vital reference for both your team and the manufacturer. Define production milestones and delivery timelines to avoid ambiguity. Acknowledge and address language and cultural differences early on. Employ bilingual project managers or interpreters to facilitate smoother interactions.

Contractual Agreements and Quality Assurance for Mechanical Seals

Robust contractual agreements protect both parties and ensure quality. Include a comprehensive quality clause. This outlines specific quality standards, required testing, and certification. It also establishes a mechanism for handling quality-related disputes. A warranty clause specifies guarantees regarding quality, performance, or durability. It details steps buyers take if problems arise. Define clear benchmarks and incorporate certifications like ISO 9001 and API 682. Outline detailed inspection procedures for pre-production, mid-production, and final stages. Specify financial penalties for non-compliance to encourage accountability. Clearly define criteria for accepting or rejecting products. Establish a structured dispute resolution process. Consult legal and industry experts for insights specific to Chinese manufacturing practices.

Confidently source high-quality seals from China in 2025. Focus on certified, innovative, and customer-centric manufacturers. These companies offer advanced solutions. Leverage their competitive advantages for your specific sealing requirements. Informed selection and thorough due diligence are the “secrets” to securing reliable products. This approach ensures successful partnerships.

FAQ

What are the primary advantages of sourcing mechanical seals from China?

Chinese manufacturers offer competitive solutions. They provide cost-effectiveness without compromising quality. They also feature advanced technology and a broad product range. Many offer extensive customization capabilities for specific industrial needs.

How do Chinese manufacturers ensure the quality of their mechanical seals?

Manufacturers adhere to international standards like ISO and API. They invest in R&D and innovation. They implement rigorous quality control, including material traceability and performance testing. Customer testimonials and certifications validate their quality commitment.

What types of mechanical seals can I find from Chinese manufacturers?

Chinese manufacturers produce various types. These include cartridge seals for easy installation, rubber bellows for flexibility, and metal bellows for high temperatures. They also offer versatile O-ring seals and custom solutions for unique demands.

What is the process for successfully partnering with a Chinese mechanical seal manufacturer?

Conduct thorough due diligence and supplier verification. Maintain clear communication and provide detailed specifications for orders. Establish robust contractual agreements and quality assurance protocols. This ensures a successful and reliable partnership.

Post time: Dec-12-2025