Proper Mechanical Seal Selection is paramount for industrial operations. The correct choice directly influences operational reliability and safety. Industry data indicates that 34% of industrial accidents involving hazardous chemicals stem from faulty or worn seals, underscoring this critical need. These failures create risks for workers, cause environmental damage, and lead to costly operational downtime. A systematic approach to specifying Mechanical Seals is therefore essential. This strategy helps prevent common problems like “Why is my mechanical seal leaking?” and informs decisions on appropriate Pump Seal Types or advanced High-temperature mechanical seal solutions. Following a comprehensive Cartridge mechanical seal installation guide also ensures optimal performance.

Key Takeaways

- Choosing the right mechanical seal is very important for factory safety and to avoid costly problems.

- Consider the liquid’s properties, temperature, pressure, and shaft speed when picking a seal.

- The seal chamber size and how the shaft moves also affect which seal works best.

- The materials used for the seal faces and other parts must match the chemicals they touch.

- Dual seals offer extra safety for dangerous liquids, and cartridge seals are easier to install and fix.

Operating Conditions for Mechanical Seals

Selecting the correct mechanical seal begins with a thorough understanding of the operating environment. These conditions directly influence seal performance and longevity.

Process Fluid Characteristics

The nature of the process fluid significantly impacts seal material selection. Engineers must consider the fluid’s corrosiveness, abrasiveness, and viscosity. Corrosive fluids demand chemically resistant materials, while abrasive slurries require hard, wear-resistant seal faces. Fluid temperature and pressure also play crucial roles. High temperatures degrade seal materials, causing premature failure. Low temperatures can make materials brittle, reducing flexibility and sealing ability. Seals with a wide temperature tolerance are essential for applications with fluctuating temperatures, such as in chemical processing plants. Here, advanced materials withstand ranges from -40°C to 200°C.

Temperature Range

Extreme temperatures severely affect mechanical seal material degradation rates. High temperatures cause permanent deformation in elastomers, leading to a loss of elasticity and sealing force. They also accelerate chemical reactions in engineering plastics and reduce the mechanical strength of metals. Seal face materials must withstand frictional heat and environmental temperatures. Inadequate cooling or improper material selection leads to localized heating, material degradation, and failure of lubricating films. Rapid temperature changes induce thermal shock, causing cracking in brittle materials like ceramics or Silicon Carbide. Temperature fluctuations cause seals to expand and contract. Repeated thermal cycling creates stress, leading to cracking, deformation, or loss of sealing ability.

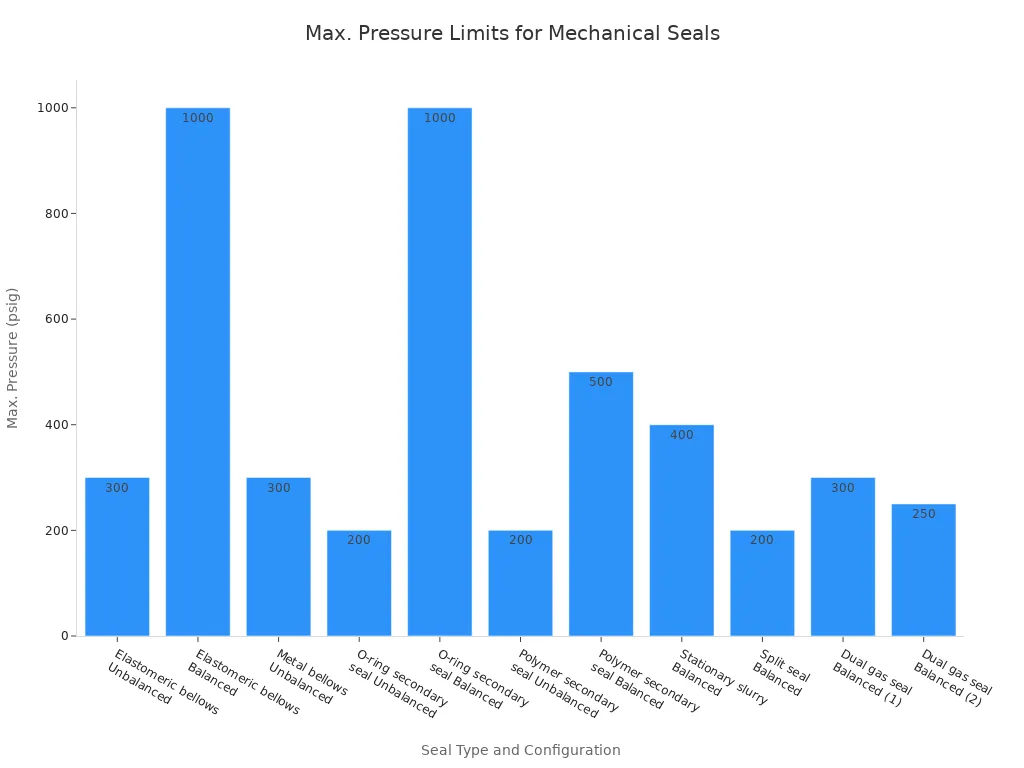

Pressure Dynamics

The system’s pressure dictates the required mechanical seal type. High-pressure applications necessitate seals capable of withstanding significant force. Seals designed for low pressure may fail to maintain integrity, causing leakage. For example, industrial pumps in oil fields require seals specifically engineered for pressures up to several thousand pounds per square inch. Different seal types handle varying pressure limits.

| Seal Type | Balanced | Unbalanced | Max. Pressure (psig) |

|---|---|---|---|

| Elastomeric bellows | x | 300 | |

| Elastomeric bellows | x | 1000 | |

| Metal bellows | x | 300 | |

| O-ring secondary seal | x | 200 | |

| O-ring secondary seal | x | 1000 | |

| Polymer secondary seal | x | 200 | |

| Polymer secondary seal | x | 500 | |

| Stationary slurry | x | 400 | |

| Split seal | x | 200 | |

| Dual gas seal | x | 300 | |

| Dual gas seal | x | 250 |

High-pressure rotary seals handle up to 3,500 psi (240 bar) typically. Special designs reach up to 10,000 psi (700 bar) at low surface speeds. For pressures exceeding 3,000 psi (210 bar), specialized engineering consultation becomes necessary.

Shaft Speed and Movement

Shaft speed significantly influences mechanical seal performance and lifespan. Higher rotational speeds generate more friction between the seal faces. This increased friction directly leads to higher temperatures and accelerated wear. For instance, when shaft speeds exceed 500 feet per minute (FPM), engineers must reduce frictional drag. This action helps manage the high temperatures that develop under the seal lip, which otherwise makes contamination prevention difficult.

As shaft speeds climb further, reaching 3000 FPM, the primary seal lip’s pumping action degrades. At these extreme speeds, hydrodynamic aids become essential. These aids maintain proper lubrication, decrease underlip temperature, and extend the seal’s operational life. Without these measures, seals can quickly overheat and fail.

Beyond rotational speed, the type of shaft movement also impacts seal selection. Axial movement, or movement along the shaft’s axis, requires seals that can accommodate this displacement without losing their sealing integrity. Radial movement, or movement perpendicular to the shaft’s axis, demands seals capable of handling slight shaft deflections or runout. Excessive movement in either direction can cause premature wear or seal failure. Therefore, engineers must select Mechanical Seals specifically designed to tolerate the expected shaft dynamics of the application. This ensures reliable operation and prevents unexpected downtime.

Equipment Design Influencing Mechanical Seals

Equipment design significantly impacts the selection of appropriate Mechanical Seals. Engineers must consider the physical constraints and operational characteristics of the machinery. These factors directly affect seal fit, performance, and longevity.

Seal Chamber Dimensions

The seal chamber’s dimensions are critical for proper seal installation and function. The chamber must provide adequate space for the chosen seal type, including its primary and secondary sealing elements. Insufficient space can lead to improper seating, premature wear, or complete seal failure. Conversely, an oversized chamber might allow excessive movement, compromising sealing integrity. Manufacturers design seal chambers to accommodate specific seal types, ensuring optimal performance. Therefore, precise measurements of the chamber bore, depth, and shaft diameter are essential before selecting a seal.

Shaft Runout and Deflection

Shaft runout and deflection directly influence a mechanical seal‘s ability to maintain a consistent seal face. Runout refers to the deviation of the shaft’s surface from its true rotational axis. Deflection describes the bending of the shaft under load. Both conditions create dynamic stress on the seal faces and secondary sealing elements. Excessive runout or deflection causes uneven wear, increased leakage, and reduced seal life. For most pumps and sealing systems, the acceptable radial shaft runout should fall between 0.002 to 0.005 inches (0.05 – 0.13 mm). Exceeding these limits necessitates a seal design capable of accommodating greater movement or requires equipment repair.

Available Installation Space

The physical space available for seal installation often dictates the type of seal an engineer can choose. Some applications have very limited axial or radial clearance. This constraint might prevent the use of larger, more complex cartridge seals. Component seals, which require individual assembly, often fit into tighter spaces. However, cartridge seals offer easier installation and reduced potential for human error. Engineers must balance the benefits of different seal types against the practical limitations of the equipment’s design. They must also consider space for auxiliary systems like flush lines or cooling connections.

Material Selection for Mechanical Seals

Material selection is a critical step in choosing the right Mechanical Seals. The materials directly influence the seal’s resistance to wear, corrosion, and temperature extremes. Proper material choice ensures long-term reliability and prevents premature failure.

Primary Seal Face Materials

Primary seal face materials must withstand harsh operating conditions. They experience direct contact and friction. For corrosive process fluids, engineers often select specific materials. Carbon graphite blends are generally chemically inert and self-lubricating. Acid-grade carbon graphite faces, without resin filler, work well in highly corrosive applications. Silicon carbide is the most common hard face material. It offers high chemical resistance. Specific grades exist:

- Reaction bonded silicon carbide contains free silicon metal. This limits chemical resistance. Avoid it in strong acids (pH < 4) and strong bases (pH > 11).

- Direct sintered silicon carbide (self-sintered) offers greater chemical resistance. It lacks free silicon metal. This material resists most chemicals. It suits almost any mechanical seal application.

Tungsten carbide is another common hard face material. Nickel-bound tungsten carbide is now more common. It provides broader chemical resistance.

Secondary Sealing Elements

Secondary sealing elements, such as O-rings and gaskets, provide static sealing. Their chemical compatibility is crucial. Manufacturers provide chemical compatibility information for O-rings as a general guideline. These recommendations typically apply at 70°F. Customers must test and verify the seal material for each specific application. No two situations or installations are identical. Independent verification is strongly recommended before production use.

| Material Type | Specific Material | Chemical Compatibility Characteristics |

|---|---|---|

| Elastomeric | Nitrile/Buna-N (NBR) | Low-cost, general-purpose for lower temperature water, oil/grease |

| Elastomeric | Fluoroelastomer (FKM) | Good chemical compatibility, higher operating temperature range |

| Elastomeric | EPDM | Good compatibility in water and steam; not compatible with hydrocarbons |

| Thermoset Plastic | PTFE | Chemically inert |

| Metal Alloy | Stainless steel (316, 316L) | Corrosion resistant |

Metal Components Compatibility

Metal components in a mechanical seal, like springs and glands, also require careful material selection. They must resist corrosion from the process fluid and the surrounding environment. Stainless steel, Hastelloy, and other exotic alloys offer varying degrees of corrosion resistance. Engineers match these materials to the specific chemical environment. This prevents pitting, cracking, and other forms of degradation.

Mechanical Seals Configuration and Type

The configuration and type of a mechanical seal significantly influence its suitability for specific applications. Engineers must carefully consider these design choices to ensure optimal performance and safety.

Single Versus Dual Seal Arrangements

Seal arrangements vary based on application needs. Single seals are common for non-hazardous fluids. However, dual seal arrangements, specifically double mechanical seals, offer greater protection. They are preferred for process safety when dealing with toxic or hazardous fluids. Any leakage from these fluids poses a significant risk due to stringent environmental regulations. Dual seals provide substantially greater protection against leaks. The tandem arrangement, with two seals mounted in the same orientation, is particularly recommended for toxic or hazardous applications. The outboard seal acts as a full pressure backup, providing a safety net if the inboard seal fails. Double cartridge mechanical seals are favored for applications where reliability and safety are paramount. Their tandem design provides a secondary sealing barrier, enhancing protection against leaks and environmental contamination. This is crucial for maintaining product purity and safety in critical applications.

Balanced Versus Unbalanced Seals

Seal balance refers to how pressure acts on the seal faces. Unbalanced seals are simpler and cost less. They work well in low-pressure applications. Balanced seals are recommended for systems with high-pressure pumps operating at 10 barg or more. They have tighter tolerances and a more stable balance. Using balanced seals in high-pressure applications prevents risks such as leaks, associated hazards, and system downtime. They offer greater reliability and long-term cost savings. Balanced seals distribute pressure more evenly, minimizing friction and heat production. This prevents damage to seal faces and materials. Lower temperatures and less friction lead to reduced wear and tear, increasing the seal’s operational lifespan. They also resist thermal cracking.

Cartridge Versus Component Seals

The choice between cartridge and component seals impacts installation and maintenance. Component seals require individual assembly. This demands skilled technicians for installation and precise measurements to prevent seal failure. This increases operator time and installation cost. Cartridge seals offer easy and simple installation. They often do not require specialists. This leads to reduced installation costs and downtime. Cartridge seals are much easier to replace because all components are self-contained. This allows for simple swapping without disassembling the pump, saving significant time and money. Mechanical cartridge seals are much easier to fit as they are preassembled. They allow direct insertion without complex adjustments, thus reducing error risk.

Practical and Economic Factors for Mechanical Seals

Engineers consider practical and economic factors when selecting Mechanical Seals. These elements influence long-term operational success and cost efficiency.

Maintenance and Serviceability

Maintenance requirements significantly impact seal selection. Different seal types offer varying serviceability. For example, cartridge seals generally offer a longer service life. Their pre-assembled nature minimizes installation errors. This reduces the need for frequent maintenance. Conversely, component seals require individual assembly. This increases installation time and potential for error. The expected lifespan also varies by seal type:

| Type of Mechanical Seal | Expected Lifespan Range |

|---|---|

| Single Spring | 1 – 2 years |

| Cartridge | 2 – 4 years |

| Bellows | 3 – 5 years |

Balanced seals achieve extended lifespans in high-pressure systems. They evenly distribute hydraulic forces. Metal bellows seals are resilient in high-temperature applications. They effectively manage thermal expansion. Mixer seals face unique challenges from abrasive particles. Their lifespans depend on mixing intensity and material abrasiveness.

Cost-Effectiveness and Lifecycle Costs

The initial cost of a mechanical seal is only one part of its total expense. Lifecycle cost (LCC) provides a more comprehensive view. LCC includes purchase, installation, operation, maintenance, environmental, decommissioning, and disposal costs. A seal with a higher initial acquisition cost can ultimately have a lower total LCC. This happens due to reduced operating and maintenance expenses. Factors like energy consumption and mean time between repair (MTBR) play a role. For instance, an engineered single seal might cost more initially. However, it can offer significant savings over 15 years compared to other sealing systems. This is due to lower operating and maintenance costs.

Industry Standards and Regulations

Adherence to industry standards ensures safety and reliability. API Standard 682, “Pumps – Shaft Sealing Systems for Centrifugal and Rotary Pumps,” is a leading industrial standard. It outlines requirements for Mechanical Seals and sealing systems. This standard is primarily used in the petroleum, natural gas, and chemical industries. API 682 provides a common framework for seal design, testing, and selection. Its main objectives include:

- Ensuring reliability and safety in hazardous and high-pressure environments.

- Standardizing seal types, arrangements, and testing across industries.

- Facilitating interchangeability of mechanical seals between manufacturers.

Adhering to API 682 helps industries mitigate risks of seal failure, leakage, and downtime. This ensures smooth operations.

A holistic approach to Mechanical Seals selection is crucial for operational success. Informed decisions yield significant long-term benefits, including enhanced reliability, improved safety, and reduced operational costs. Collaborating closely with Mechanical Seals manufacturers ensures optimal solutions. This partnership provides seals precisely tailored to specific application needs, guaranteeing peak performance and safety.

FAQ

What is the most critical factor when selecting a mechanical seal?

The process fluid’s characteristics are paramount. Engineers must consider its corrosiveness, abrasiveness, and viscosity. These properties directly dictate the necessary seal materials for optimal performance and longevity.

Why do engineers prefer dual seal arrangements for hazardous fluids?

Dual seals provide enhanced safety and environmental protection. They offer a secondary barrier against leaks, which is crucial for toxic or hazardous applications. This design minimizes risks and ensures compliance with stringent regulations.

What is the primary difference between balanced and unbalanced mechanical seals?

Balanced seals distribute pressure more evenly across the seal faces. This design reduces friction and heat, extending seal life in high-pressure applications. Unbalanced seals are simpler and suitable for lower pressure systems.

How do temperature fluctuations impact mechanical seal performance?

Temperature fluctuations cause materials to expand and contract. This thermal cycling creates stress, leading to cracking, deformation, or loss of sealing ability. Engineers must select seals with wide temperature tolerances for such conditions.

Post time: Dec-25-2025