Ningbo Victor Seals Co., Ltd, established in 1998, is a professional manufacturer of Mechanical Seals in Ningbo, Zhejiang province. Our brand “Victor” is registered in over 30 countries worldwide. We understand the critical role Mechanical Seals play in various industrial processes, and our expertise helps address common challenges.

Our comprehensive range of Mechanical Seals includes cartridge seals, rubber bellow seals, metal bellow seals, and O-ring seals, designed for diverse working conditions. We also provide OEM Mechanical Seals tailored to specific customer demands. We recognize that understanding the primary Mechanical Seal Failure Causes is essential for reliable operation. Our products are engineered to minimize these issues, ensuring optimal performance.

Effective Mechanical Seal Troubleshooting often involves identifying problems early. Our seals are designed with precision, and we produce different spare parts from materials like Silicon Carbide, Tungsten Carbide, Ceramic, and Carbon for seal rings, bushings, and thrust discs. Examining Seal Face Wear Patterns offers crucial insights into performance, and our high-quality materials contribute to extended seal life.

Engineers frequently inquire about What causes heat checking on mechanical seal faces? Our seals are manufactured to stringent standards (DIN24960, EN12756, IS03069, AP1610, AP1682, and GB6556-94) to resist such issues. Furthermore, we understand the importance of How to prevent chemical corrosion of seal elastomers? Our commitment to quality materials and design ensures the long-term integrity of our seals, even in challenging environments.

Our products are widely used in petroleum, chemical industry, power plants, machinery, metallurgy, shipbuilding, sewage treatment, printing and dyeing, food industry, pharmacy, automobile, and more, demonstrating our commitment to providing reliable and durable Mechanical Seals.

Key Takeaways

- Install mechanical seals correctly. Bad installation is a top reason for seals to fail early. Follow all steps and use the right tools.

- Keep mechanical seals lubricated. Seals need a fluid film to work well. Dry running causes seals to get too hot and break down fast.

- Protect seals from dirt and chemicals. Abrasive particles and wrong chemicals can damage seals. Use filters and choose materials that can handle the fluids.

- Control temperature and vibration. Too much heat or shaking can harm seals. Use cooling systems and fix things that cause vibration to make seals last longer.

- Check seals regularly and upgrade materials. Look for signs of wear and tear. Using stronger materials like silicon carbide can make seals more durable.

1. Improper Installation of Mechanical Seals

Improper installation stands as a leading cause of premature mechanical seal failure. Even the most robust and high-quality Mechanical Seals cannot perform optimally if technicians install them incorrectly. This issue often stems from a lack of proper training, rushing the installation process, or neglecting critical steps.

Consequences of Misalignment and Incorrect Setting

Misalignment and incorrect setting create significant operational problems. A substantial percentage of mechanical seal failures are attributed to vibration induced by misalignment. This misalignment can manifest in several ways:

- Parallel (offset) misalignment: Shafts are offset but remain parallel.

- Angular misalignment: Shafts intersect at an angle.

- Combination of both: Real-world installations often exhibit a mix of parallel and angular misalignment.

Shaft misalignment causes deflection at the seal location. This deflection disturbs the lubricating film between the seal faces. Even minor deflection leads to uneven seal face loading, increased friction, and localized heat buildup. These conditions rapidly degrade seal performance and lead to failure.

Incorrect setting also has severe consequences.

- Setting the pressure in the seal housing too high or too low can lead to seal failures.

- Drive problems causing high runout of the agitator shaft can result in seal failures.

- Running the agitator with the liquid at blade level can cause seal failures.

- For dry seals, incorrect operation can lead to higher than normal nitrogen consumption, hissing or puffing sounds from the seal housing, and indicator ball readings above allowable limits or bouncing in the flowmeter.

- For lubricated or wet seals, improper performance is indicated by an increased rate of liquid loss or the seal running totally dry.

- Leaking wet seals introduce barrier fluid into the batch, causing contamination. They can also leak into the atmosphere and onto the vessel head, creating a mess. Eventually, the lubricator runs dry, leading to seal failure and potential release of vessel contents.

- Leaking dry seals consume a significant amount of nitrogen, wear out, and can over-pressurize small vessels. For face seals, a large amount of fine carbon dust can enter and contaminate the batch. This eventually leads to seal wear-out, inability to maintain barrier gas pressure, and atmospheric release of vessel contents.

Best Practices for Mechanical Seal Installation

Following industry-standard best practices ensures proper installation and extends seal life.

- Pre-installation Planning and Inspection: This involves identifying the seal type, material, and operating conditions. It also includes inspecting components like the shaft, sleeve, gland, and seal faces for wear. Technicians measure shaft runout and diameter against manufacturer tolerances. They confirm all necessary parts are present.

- Pre-installation Checklist: Utilize a standardized checklist to ensure the correct seal model and material. Verify the shaft/sleeve are within tolerance. Ensure a clean environment is available. Calibrated tools are ready, approved lubricants are on hand, and new O-rings/backup rings are present. Document all pre-installation measurements.

- Tools, Consumables, and Workspace Setup: Prepare a clean, well-lit, and contaminant-free area. Essential tools include a torque wrench, feeler gauges, micrometer/caliper, dial indicator, soft-jawed vice, manufacturer-approved assembly grease, solvent, lint-free wipes, and calibrated measuring tools. For cartridge seals, verify the correct gland stud pattern and torque sequence.

2. Poor Lubrication and Dry Running Conditions

How Inadequate Lubrication Damages Mechanical Seals

Inadequate lubrication severely compromises the performance and lifespan of mechanical seals. Most mechanical seals rely on a fluid film between their faces to reduce heat and friction. When this lubrication is insufficient or absent, dry running occurs. This condition causes immediate and severe overheating. The lubricating film between seal faces can vaporize, leading to thermal shock. This shock often results in cracking, blistering, and rapid abrasive wear of the seal faces.

Operators observe several signs of inadequate lubrication. Deep grooves on the seal face often indicate this problem. Other symptoms include squealing noises, carbon dust accumulation, and scratches or scoring on the seal faces. Heat damage to pump components also points to insufficient lubrication. Failure of the flush system or insufficient process fluid at the seal faces generates excessive heat. This heat causes scorched or discolored seal faces and shortens seal life. Dry running also leaves concentric grooves on the seal face. “Flashing off” describes the explosive evaporation of media in the sealing gap. This phenomenon causes the seal faces to chatter and crater. Low lubricity increases the likelihood of cavitation at the seal faces. This leads to intermittent dry running, heat, wear, and leakage.

Strategies to Ensure Proper Lubrication for Mechanical Seals

Proper lubrication is crucial for extending the lifespan of Mechanical Seals. It reduces friction and wear, preventing premature failure. This also decreases maintenance costs and downtime. Effective lubrication minimizes leakage, which is vital for safety and environmental compliance. It also increases reliability, leading to smoother operation and fewer unexpected breakdowns.

Different systems ensure proper lubrication. Internal lubrication uses the pumped fluid itself. This system is cost-effective when the pumped fluid is a good lubricant. External lubrication uses a separate fluid. This is ideal when the pumped fluid is not suitable. Buffer and barrier systems are more sophisticated. They use a low-pressure or higher-pressure fluid for hazardous or sensitive fluids. These systems offer the highest safety.

Several factors influence lubricant choice. High operating temperatures can degrade lubricants. High pressures can cause lubricants to leak. Higher speeds generate more friction and heat. The lubricant must also be compatible with the process fluid. Regular inspections are essential for early problem detection. This includes checking for leaks, wear, and lubricant levels. Lubricant management involves using the correct type and keeping it clean. Routine maintenance tasks include lubricant replenishment and filter replacement. Prompt investigation of anomalies prevents seal failure.

3. Abrasive Media and Contamination in Mechanical Seals

The Destructive Impact of Abrasive Particles

Abrasive particles and contamination significantly reduce the lifespan of Mechanical Seals. These particles, often present in the process fluid, directly damage seal faces. For example, irregular SiO2 abrasive particles can cause damage, and experiments analyze their fracture mechanisms at the sealing interface. During drilling processes, particles and debris, including rock fragments, enter the sealing interface. This leads to severe abrasive wear. These abrasive particles cause scratches, cracks, or uneven wear on the essential parts of a mechanical seal.

Abrasive particles degrade mechanical seal components primarily through abrasive wear when they invade the sealing interface. The degradation mechanisms depend on the particle’s motion. If particles become embedded, they act as cutting tools, causing two-body abrasion. If they remain free, their motion can involve both sliding and rolling. Regardless of their movement, the wear loss results from the shearing and stretching effects these particles exert on the rubber. Thermal degradation of the rubber can alter its mechanical properties, making it more susceptible to particle penetration. This change can shift the wear mechanism from surface tearing to micro-cutting or fleck peeling. Furthermore, particles can become trapped in surface defects, which prolongs their abrasive action and can change their motion from sliding to rolling, thereby intensifying the damage to the seal components.

Filtration and Material Selection for Abrasive Environments

Protecting mechanical seals in abrasive environments requires effective strategies. Filtration systems are crucial for removing larger solids. This is particularly important in applications like mining, where flush water can introduce abrasive particles if not properly filtered. Proper filtration strategies, specifically using fine filters, are essential for buffer and barrier fluids in mechanical seals. This removes impurities, mitigates abrasive wear, and protects seal performance. It is important to ensure filters are compatible with the fluids to avoid introducing new contaminants or restricting flow. Selecting appropriate materials for seal faces and secondary seals also plays a vital role. Harder materials, such as silicon carbide or tungsten carbide, offer superior resistance to abrasive wear compared to softer materials.

4. Chemical Incompatibility with Mechanical Seal Materials

Chemical Attack and Degradation of Mechanical Seals

Chemical incompatibility poses a significant threat to the integrity of Mechanical Seals. When seal materials encounter incompatible process fluids, chemical attack and degradation occur. This process compromises the seal’s ability to function effectively. Common chemical agents cause various forms of damage to seal faces, elastomers, and other seal components. For instance, hydrocarbon-based oils attack elastomers like EPDM, while solvents such as acetone and ethanol degrade materials such as nitrile.

Strong acids, alkalis, or aggressive solvents can break down the molecular structure of specific rubber formulations. Fluids causing absorption lead to swelling and weakening of elastomers. Strong oxidizing chemicals or oils that extract plasticizers can make O-rings hard, brittle, and stiff. Environmental factors like ozone, oxygen, or UV light chemically react with vulnerable rubbers, causing cracking. Petroleum-based oils or fuels can cause softening and swelling in incompatible rubbers like Nitrile (Buna-N). Cleaning agents, acidic media, and caustic flushes also demand careful consideration of chemical compatibility. High pH environments and thermal effects require alkali-resistant materials.

Selecting Chemically Resistant Mechanical Seal Components

Selecting the correct materials for Mechanical Seals is crucial for preventing chemical degradation. Engineers must consider several criteria when choosing chemically resistant components. The operating environment is paramount; this includes temperature, pressure, and the presence of abrasive or corrosive fluids. Materials must possess excellent thermal stability for high-temperature applications. Compatibility with the process media is fundamental. Materials must resist aggressive chemicals, oils, or gases to prevent chemical reactions, degradation, or swelling. This requires considering the primary chemical, secondary compounds, reaction byproducts, and cleaning agents. pH levels are crucial, as are oxidizing chemicals and the concentration of corrosive agents.

Temperature and pressure performance characteristics are also vital. Elevated temperatures accelerate chemical attack and alter material properties. High pressures exacerbate chemical attack and impose mechanical stresses. Therefore, materials need high compressive strength, such as silicon carbide or tungsten carbide. Surface finish and wear resistance requirements also play a role. Surface quality affects lubricating films and creates sites for chemical attack. Hard materials, like tungsten carbide or silicon carbide, are necessary when process fluids contain suspended solids.

5. Excessive Temperature Effects on Mechanical Seals

Thermal Stress and Its Impact on Mechanical Seal Integrity

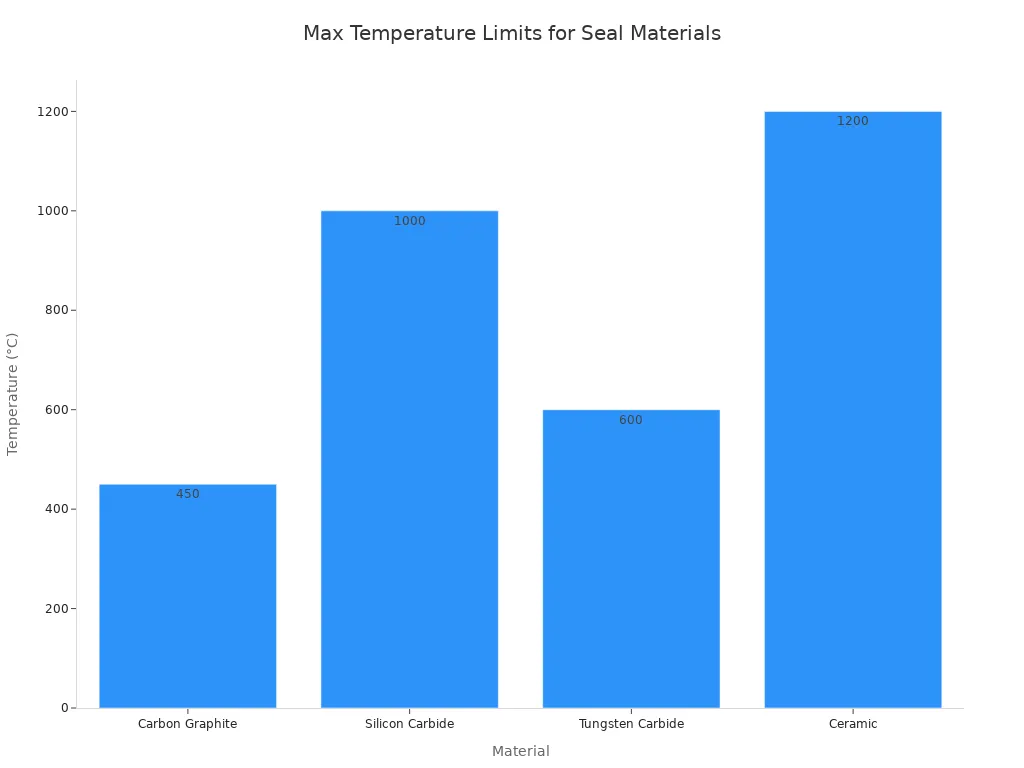

Excessive temperatures significantly compromise the integrity and lifespan of Mechanical Seals. High temperatures cause thermal stress, leading to various forms of damage. Frictional heat generation is a primary concern. Inadequate cooling or incorrect material choices lead to localized heating. This causes material degradation or failure of lubricating films. Materials like Silicon Carbide and Tungsten Carbide offer high thermal conductivity for better heat dissipation. Carbon, while self-lubricating, can overheat. Inefficient cooling systems warp or glaze seal faces. Excessive heat degrades lubricating films, causing dry contact and wear.

Temperature fluctuations also cause face distortion or thermal cracking. Uneven expansion between mating parts, due to differing thermal expansion coefficients, leads to misalignment and leakage. Thermal gradients cause out-of-flatness or bowing, affecting sealing pressure and creating hot spots. Rapid temperature changes induce thermal shock, especially in brittle materials like ceramics, leading to cracking. High pressure and temperature combinations accelerate fatigue and stress fractures. Furthermore, elevated temperatures accelerate chemical reactions between seal materials and process media. This causes swelling, softening, or cracking. Temperature changes can cause process fluids to flash, leading to vapor lock or dry running. Increased temperature often decreases fluid viscosity, reducing lubrication and increasing wear.

Different materials have varying temperature tolerances:

| Elastomer Material | Temperature Range |

|---|---|

| Nitrile Rubber (NBR) | -40°C to 120°C |

| Fluorocarbon Rubber (FKM) | -20°C to 200°C |

| EPDM | -50°C to 150°C |

| Material | Temperature Range |

|---|---|

| Carbon Graphite | -200°C to 450°C |

| Silicon Carbide | Up to 1000°C |

| Tungsten Carbide | Up to 600°C |

| Ceramic | Up to 1200°C |

Cooling Systems and High-Temperature Mechanical Seal Solutions

Managing excessive temperatures is crucial for seal longevity. Cooling systems effectively prevent seal overheating. These solutions dissipate heat and maintain optimal operating conditions for seals.

Several types of cooling systems are effective:

- Circulation of Cooling Fluid: This involves circulating a cooling fluid, such as water or a water-glycol mixture, through a dedicated system. This system includes a pump, heat exchanger, and controls to dissipate heat from seal faces.

- Heat Exchangers: These devices transfer heat from the process fluid to a cooling medium, like air or water. They remove heat generated within the equipment and cool mechanical seals.

- External Cooling Systems: Systems like chillers or refrigeration units maintain the temperature of the process fluid and surrounding environment. They offer a comprehensive cooling approach.

- Heat Dissipation Devices: Devices such as cooling fins, heat sinks, or thermal conductive materials increase surface area for heat dissipation. They promote efficient cooling of seal components.

- Integrated Cooling Features: Modern seals may include cooling jackets or channels for direct circulation of cooling fluid within the seal assembly. This optimizes thermal performance.

6. Vibration and Its Detrimental Impact on Mechanical Seals

Excessive vibration poses a significant threat to the longevity and performance of Mechanical Seals. This dynamic force can originate from various sources within a pumping system, leading to premature failure. Understanding these sources and their effects is crucial for effective prevention.

How Excessive Vibration Leads to Mechanical Seal Failure

Vibration directly compromises the sealing interface. It causes the rotating seal face to wobble unevenly against the stationary seal face. This wobbling creates impact loads on the seal faces with each shaft rotation. These impacts disrupt the even distribution of lubricating fluid between the faces. Without uniform lubrication, friction builds up, generating excessive heat across the seal faces. This combination of impact and heat directly leads to damage and eventual failure of the mechanical seal.

Several factors contribute to excessive vibration. Mechanical causes include unbalanced rotating components like damaged impellers or bent shafts. Misalignment between the pump and driver, pipe strain, and worn bearings also generate vibration. Hydraulic causes involve operating the pump away from its best efficiency point (BEP), vaporization of the pumped product, or air ingress into the system. Other sources include harmonic vibration from nearby equipment or operating the pump at a critical speed. Misalignment between pump and motor shafts, combined with system vibration, creates stress. This stress causes uneven wear and premature fatigue, ultimately leading to seal failure.

Mitigating Vibration to Protect Mechanical Seals

Protecting mechanical seals from vibration requires proactive measures. Engineers can implement several solutions to reduce vibration levels and enhance seal resilience. Material selection plays a vital role. Polyurethane seals, for instance, maintain flexibility under extreme conditions. They absorb shocks and vibrations without cracking or losing shape. These materials offer excellent wear resistance, outperforming rubber in high-vibration environments. They also resist compression set, ensuring consistent sealing performance.

Other engineering solutions include the use of dampers and isolators. Dampers utilize visco-elastic materials to reduce resonant behavior within the system. Isolators, made from compliant materials like die-cut gaskets or molded rubber components, mitigate vibration transmission. These components absorb shock and dampen vibrations, protecting sensitive seal parts. Custom-molded rubber and plastic solutions can also serve as isolator seals, guarding against contaminant ingress, shock, and vibration.

7. Pressure Fluctuations Affecting Mechanical Seals

The Challenges of Unstable Pressure on Mechanical Seals

Unstable pressure conditions significantly challenge mechanical seal performance. Increased pressure can deform the seal faces. This deformation compromises the sealing integrity. Secondary seals, such as O-rings and bellows, also degrade under increased pressure. Cyclic pressure changes cause seals to repeatedly compress and relax. This leads to material fatigue and eventual failure if the seal lacks sufficient resilience. Abrupt pressure spikes can exceed the material’s elastic deformation capability. This results in permanent deformation or cracking.

Dynamic pressure, caused by fluid movement, leads to seal face vibration. This vibration causes wear and premature failure. Fluctuating pressure affects the thickness and stability of the fluid film between seal faces. If the film is too thin, metal-to-metal contact and increased wear occur. If it is too thick, instability and leakage can result. Unstable pressure conditions commonly arise from operating conditions that exceed the seal’s design parameters. Hydraulic imbalances within the seal chamber also contribute. When system pressures surpass design limits, the increased closing force leads to excessive friction and heat. Conversely, insufficient pressure causes leakage due to improper seal face contact. Hydraulic imbalances create fluctuating pressures, leading to “face lifting.” This intermittent contact prevents stable lubrication and causes thermal cycling, contributing to instability.

Designing and Operating Mechanical Seals for Variable Pressure

Designing and operating Mechanical Seals for variable pressure requires careful consideration. Mechanical seal faces are susceptible to distortions caused by pressure and temperature gradients. As pressure and speed fluctuate, these distortions also change, impacting the face profile and potentially leading to wear. While modern seals are generally robust, significant variations in speed can negatively affect seal life. Mechanical seal environment control systems, such as API Plan 11, 21, and 31, are highly sensitive to pressure changes. These systems must accommodate maximum and minimum operating conditions to prevent issues like elastomer or face damage and ensure proper cooling and lubrication.

Operating conditions, particularly pressure and shaft speed, are critical factors in selecting a suitable mechanical pump seal for variable pressure environments. High-pressure applications necessitate a robust seal design capable of withstanding significant fluid pressure forces. A crucial design consideration involves appreciating the entire engineering system and application conditions. It is vital to consider the full operating spectrum, including pressure cycles, starts and stops, and varying temperatures. Balanced mechanical seals are crucial for variable pressure conditions. They distribute hydraulic forces evenly across the seal faces. This design minimizes pressure-induced deformation, reduces heat generation and wear, and extends the seal’s lifespan.

8. Material Fatigue and Wear in Mechanical Seals

Understanding the Lifespan and Degradation of Mechanical Seals

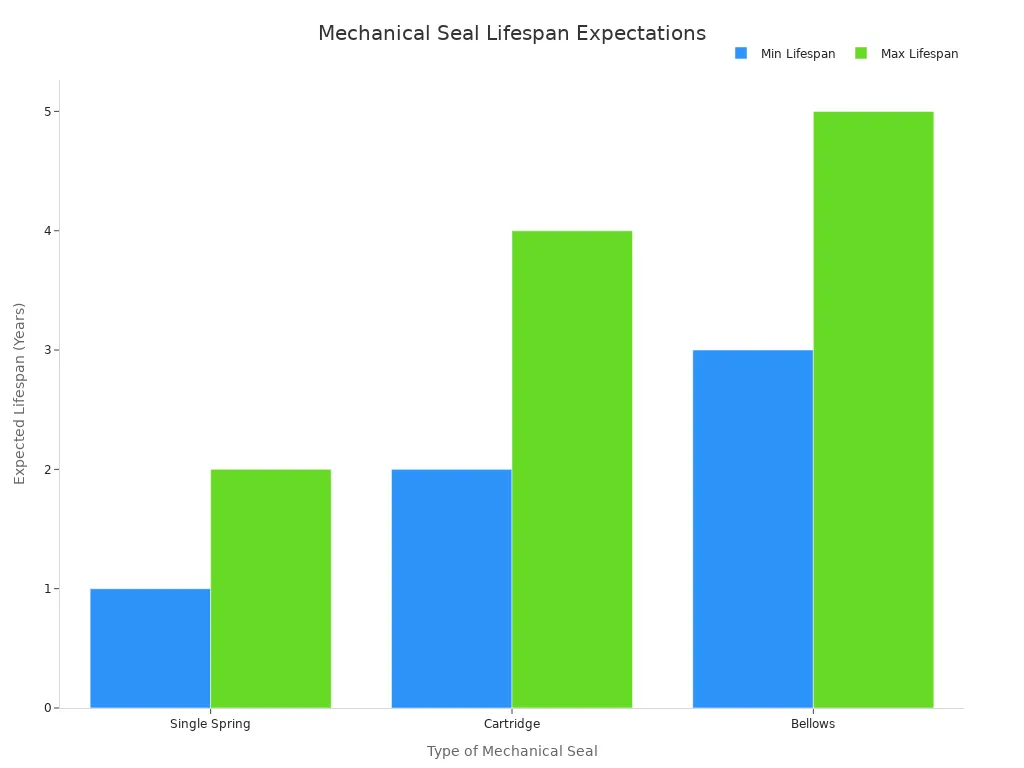

Material fatigue and wear represent common causes of failure for Mechanical Seals. Over time, the constant stress and friction from operation degrade seal components. This degradation reduces the seal’s effectiveness and eventually leads to failure. Understanding the expected lifespan helps in planning maintenance.

| Type of Mechanical Seal | Expected Lifespan Range |

|---|---|

| Single Spring | 1 – 2 years |

| Cartridge | 2 – 4 years |

| Bellows | 3 – 5 years |

These ranges are typical. Actual lifespans vary based on operating conditions and maintenance practices. Several indicators show material fatigue and wear:

- Grooving: Axial cuts on the dynamic lip often come from contamination.

- Swelling: The seal material becomes soft and loses shape. Incompatible media usually causes this.

- Deterioration: The seal loses elasticity, cracks, and crumbles. Incompatible fluid media often causes this.

- Hardening: Cracking and loss of flexibility occur. Seals exposed to low temperatures beyond material limits cause this.

- Scarring: Dents, cuts, or excessive scratches appear on the lip or dynamic side. Installation damage often causes this.

- Wear: A glossy, mirror-like shine or egg-shaped wear appears on the dynamic face of the seal lip. Overly fine surface finishes or insufficient lubrication cause this.

- Extrusion: Corners of the seal protrude into gaps. Nibbling damage on elastomer seals occurs. Over-pressurization, lack of a back-up ring, excessive extrusion gaps, or insufficiently hard sealing materials cause this.

- Fracture: Long linear cracks, missing chunks, or complete breaking-off of seal portions occur. Insufficiently strong materials under excessive stress, extreme low temperatures, or over-pressurization usually cause this.

Proactive Maintenance and Material Upgrades for Mechanical Seals

Proactive maintenance strategies significantly extend the lifespan of seals. These strategies minimize unexpected breakdowns. They also improve overall equipment reliability.

- Routine Maintenance Practices: This involves regular cleaning of seal components. It includes proper lubrication techniques. Monitoring system pressures and temperatures is also important. Inspecting the seal environment for issues like fluid levels and contamination helps.

- Advanced Maintenance Techniques: These include seal face reconditioning. Replacing elastomers and gaskets is part of this. Utilizing pressure relief valves and flushing systems helps. Employing buffer fluids and secondary seals provides enhanced protection.

- Best Practices for Maximizing Seal Life: Key practices ensure correct alignment during installation. Selecting appropriate materials for the specific application is crucial. Training operators on proper usage and maintenance helps. Regularly reviewing operating conditions also extends seal life.

Material upgrades also play a vital role. Using advanced materials like silicon carbide or tungsten carbide improves resistance to wear and fatigue. These materials withstand harsh conditions better. They offer superior durability.

The various factors discussed do not operate in isolation. They often combine, accelerating the degradation of Mechanical Seals. A holistic approach is crucial for extending seal longevity. This involves carefully considering fluid characteristics, including viscosity and chemical compatibility. It also includes operating conditions such as pressure and temperature. Equipment details and material options are also vital. Engineers must also evaluate practical and economic factors. This comprehensive strategy ensures optimal performance and minimizes costly downtime through informed prevention.

FAQ

What is the most common reason for mechanical seal failure?

Improper installation is the leading cause. Misalignment, incorrect setting, and rushing the process often lead to premature failure. Proper training and adherence to best practices are crucial for preventing these issues.

How does dry running affect mechanical seals?

Dry running removes the essential fluid film between seal faces. This causes immediate overheating, thermal shock, and rapid wear. It leads to cracking, blistering, and deep grooves on the seal faces, significantly shortening seal life.

Which materials are best for abrasive or chemical environments?

For abrasive conditions, hard materials like silicon carbide or tungsten carbide offer superior resistance. For chemical environments, selecting materials chemically compatible with the process fluid is vital. This prevents degradation, swelling, or cracking of seal components.

How do high temperatures impact mechanical seals?

Excessive temperatures cause thermal stress, material degradation, and lubricating film breakdown. They can lead to face distortion, thermal cracking, and accelerated chemical reactions. Cooling systems and high-temperature-resistant materials are essential for managing these effects.

Can vibration really damage a mechanical seal?

Yes, excessive vibration significantly damages mechanical seals. It causes the rotating seal face to wobble, creating impact loads and disrupting lubrication. This leads to increased friction, heat buildup, and premature wear, ultimately causing seal failure.

Post time: Jan-30-2026