Our business since its inception, usually regards product or service high-quality as organization life, continuously boost production technology, improve solution top quality and repeatedly strengthen business total top quality management, in strict accordance along with the national standard ISO 9001:2000 for multi-spring Type 2 mechanical seal for marine industry, We welcome all of the clients and friends to contact us for mutual benefits. Hope to do further business with you.

Our business since its inception, usually regards product or service high-quality as organization life, continuously boost production technology, improve solution top quality and repeatedly strengthen business total top quality management, in strict accordance along with the national standard ISO 9001:2000 for , If any product meed your demand, remember to feel free to contact us. We’re sure your any inquiry or requirement will get prompt attention, high-quality solutions, preferential prices and cheap freight. Sincerely welcome friends all over the world to call or come to visit, to discuss cooperation for a better future!

Features

•Fits equipment with confined space requirements and limited seal chamber depths in pumps, mixers, blenders, agitators, compressors and other rotary shaft equipment.

•To absorb both breakout and running torque, the seal is designed with a drive band and drive notches that eliminate overstressing of bellows. Slippage is eliminated, protecting the shaft and sleeve from wear and scoring.

•Automatic adjustment compensates for abnormal shaft-end play and run-out, primary ring wear and equipment tolerances. Axial and radial shaft movement is compensated for with uniform spring pressure.

•Special balancing allows for higher pressure applications, greater operating speeds and lower wear.

•Non-clogging, single-coil spring allows for greater dependability than multiple spring designs, and it will not run foul due to fluid contact.

Design features

• Mechanical drive – Eliminates overstressing of the elastomer bellows

• Self-aligning capability – Automatic adjustment compensates for abnormal shaft end play runout, primary ring wear and equipment tolerances

• Special balancing – Allows operation at higher pressures

• Non-clogging, single-coil spring – Not affected by buildup of solids

Recommended Applications

Process pumps

For pulp and paper

food processing,

water and wastewater

refrigeration

chemical processing

other demanding application

Operation ranges:

• Temperature: -40°C to 205°C/-40°F to 400°F (depending on materials used)

• Pressure: 2: up to 29 bar g/425 psig 2B: up to 83 bar g/1200 psig

• Speed: see enclosed speed limits chart

Combination material

ROTARY FACES: Carbon Graphite, Silicon Carbide, Tungsten Carbide

STATIONARY SEATS: Ceramic, Silicon Carbide, Tungsten Carbide, Stainless Steel

BELLOWS: Viton, EPDM, Neoprene

METAL PARTS: 304 SS standard or 316 SS option available

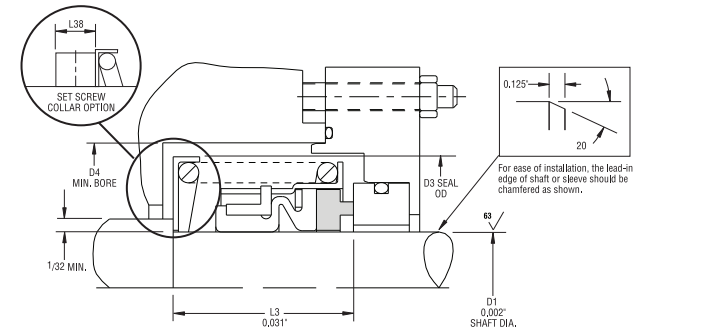

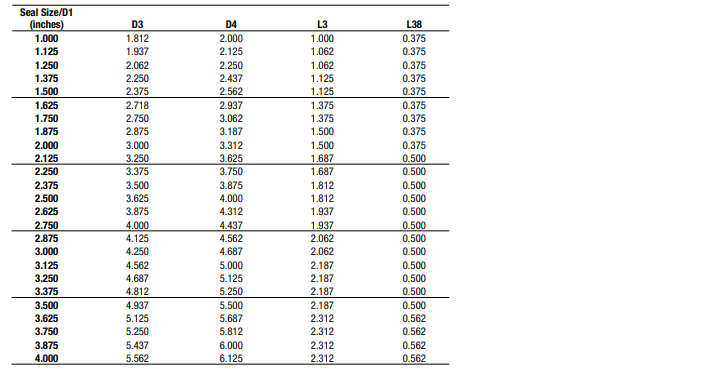

W2 data sheet of dimension(inches)

Delivery And Packing

we usually deliver the goods by express like DHL, Fedex, TNT, UPS, but we can also ship the goods by air or by sea if the goods weight and volume is big.

For the packing, we pack each seal with plastic film and then in plain white box or brown box. And then in strong carton.

multi-spring mechanical seal, water pump shaft seal