We believe that long expression partnership is actually a result of top quality, worth added services, prosperous experience and personal contact for multi-spring mechanical seal for marine industry, We honor our core principal of Honesty in business, priority in company and will do our greatest to provide our customers with high-quality goods and fantastic provider.

We believe that long expression partnership is actually a result of top quality, worth added services, prosperous experience and personal contact for , Our company follows laws and international practice. We promise to be responsible for friends, customers and all partners. We would like to establish a long-term relationship and friendship with every customer from all over the world on the basis of mutual benefits. We warmly welcome all old and new customers to visit our company to negotiate business.

Features

•Single Seal

•Dual Seal available upon request

•Unbalanced

•Multi-spring

•Bi-directional

•Dynamic O-ring

Recommended Applications

Pulp & Paper

Mining

Steel & Primary Metals

Food & Beverage

Corn Wet Milling & Ethanol

Other Industries

Chemicals

Basic (Organic & Inorganic)

Specialty (Fine & Consumer)

Biofuels

Pharmaceutical

Water

Water Management

Waste Water

Agriculture & Irrigation

Flood Control System

Power

Nuclear

Conventional Steam

Geothermal

Combined Cycle

Concentrated Solar Power (CSP)

Biomass & MSW

Operating ranges

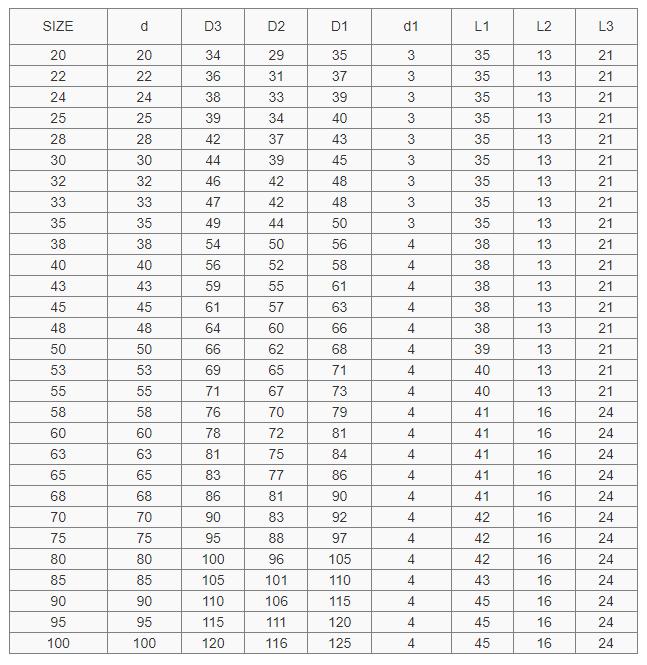

Shaft diameter: d1=20…100mm

Pressure: p=0…1.2Mpa(174psi)

Temperature: t = -20 °C …200 °C(-4°F to 392°F)

Sliding velocity: Vg≤25m/s(82ft/m)

Notes: The range of pressure, temperature and sliding velocity is depend on seals combination materials

Combination Materials

Rotary Face

Silicon carbide (RBSIC)

Tungsten carbide

Cr-Ni-Mo Sreel (SUS316)

Stationary Seat

Silicon carbide (RBSIC)

Carbon graphite resin impregnated

Auxiliary Seal

Fluorocarbon-Rubber (Viton)

Ethylene-Propylene-Diene (EPDM)

PTFE Coated VITON

PTFE T

Spring

Stainless Steel (SUS304)

Stainless Steel (SUS316)

Metal Parts

Stainless Steel (SUS304)

Stainless Steel (SUS316)

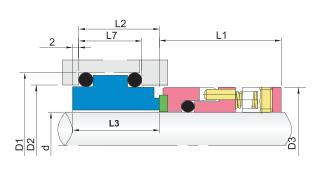

WRO data sheet of dimension (mm)

multi-spring mechanical pump seal, O ring mechanical seal