“Sincerity, Innovation, Rigorousness, and Efficiency” would be the persistent conception of our enterprise with the long-term to build with each other with consumers for mutual reciprocity and mutual advantage for multi-spring double mechanical seal for marine industry M74D, Honesty is our principle, skilled procedure is our perform, service is our target, and customers’ satisfaction is our long term!

“Sincerity, Innovation, Rigorousness, and Efficiency” would be the persistent conception of our enterprise with the long-term to build with each other with consumers for mutual reciprocity and mutual advantage for , We are confident that we’re able to provide you with opportunities and is going to be a valuable business partner of you. We look forward to working with you soon. Learn more about the types of merchandise that we work with or contact us now directly with your inquiries. You are welcome to contact us anytime!

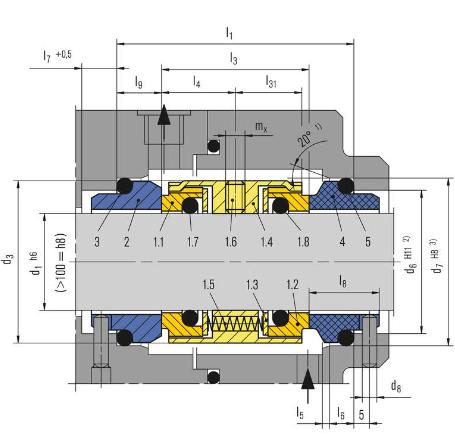

Features

•For plain shafts

•Dual seal

•Unbalanced

•Rotating multiple springs

•Independent of direction of rotation

•Seal concept based on the M7 range

Advantages

•Efficient stock keeping due to easily interchangeable faces

•Extended selection of materials

•Flexibility in torque transmissions

•EN 12756 (For connection dimensions d1 up to 100 mm (3.94″))

Recommended applications

•Chemical industry

•Process industry

•Pulp and paper industry

•Low solids content and low abrasive media

•Toxic and hazardous media

•Media with poor lubrication properties

•Adhesives

Operating range

Shaft diameter:

d1 = 18 … 200 mm (0.71″ … 7.87″)

Pressure:

p1 = 25 bar (363 PSI)

Temperature:

t = -50 °C … 220 °C

(-58 °F … 428 °F)

Sliding velocity:

vg = 20 m/s (66 ft/s)

Axial movement:

d1 up to 100 mm: ±0.5 mm

d1 from 100 mm: ±2.0 mm

Combination Materials

Stationary Ring (Carbon/SIC/TC)

Rotary Ring (SIC/TC/Carbon)

Secondary Seal (VITON/PTFE+VITON)

Spring & Other Parts (SS304/SS316)

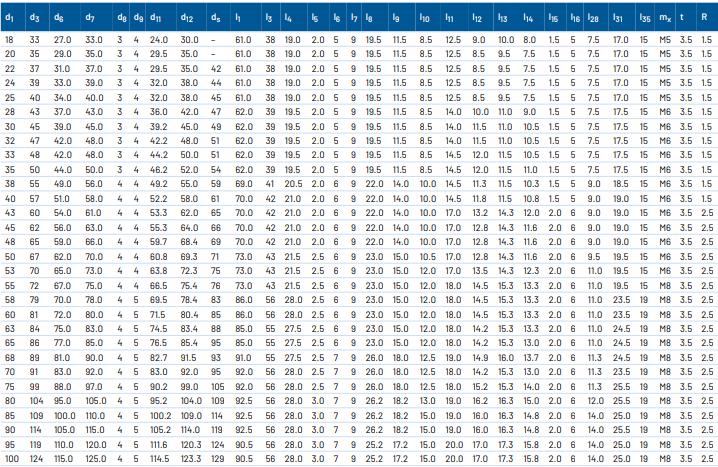

WM74D data sheet of dimension(mm)

Double face mechanical seals are designed to ensure that mechanical seals can work in a maximum sealing mode. Double face mechanical seals virtually remove leakage of the fluid or gas in pumps or mixers. Double mechanical seals provide a level of safety and minimize pump emission compliance not possible with single seals.It is essential to pump or mix a dangerous or toxic substance.

Double mechanical seals are mostly used in flammable, explosive, toxic, granular and lubricating medium. When it is used, it needs a sealing auxiliary system, that is, the isolation fluid is inserted in the sealing cavity between the two ends, thereby improving the lubrication and cooling conditions of the mechanical seal. The pump products that use double mechanical seal are: fluorine plastic centrifugal pump or IH stainless steel chemical pump, etc.

M74D mechanical pump seal, double face mechanical seal for water pump