We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of MG1 rubber bellow mechanical seal for marine pump, We always regard the technology and consumers as the uppermost. We normally do the job hard to create excellent values for our prospects and present our consumers greater products and solutions & companies.

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of , Our company has abundant strength and possesses a steady and perfect sales network system. We wish we could establish sound business relationships with all customers from at home and abroad on the basis of mutual benefits.

Replacement for below mechanical seals

AESSEAL B02, BURGMANN MG1, FLOWSERVE 190

Features

- For plain shafts

- Single and dual seal

- Elastomer bellows rotating

- Balanced

- Independent of direction of rotation

- No torsion on bellows

Advantages

- Shaft protection over entire seal length

- Protection of seal face during installation due to special bellows design

- Insensitive to shaft deflections due to large axial movement ability

- Universal application opportunities

- Important material certifications available

- High flexibility due to wide offer on materials

- Suitable for low-end sterile applications

- Special design for hot water pumps (RMG12) available

- Dimension adaptions and additional seats available

Operating Range

Shaft diameter:

d1 = 10 … 100 mm (0.39″ … 3.94″)

Pressure: p1 = 16 bar (230 PSI),

vacuum … 0.5 bar (7.25 PSI),

up to 1 bar (14.5 PSI) with seat locking

Temperature: t = -20 °C … +140 °C

(-4 °F … +284 °F)

Sliding velocity: vg = 10 m/s (33 ft/s)

Admissible axial movement: ±2.0 mm (±0,08″)

Combination Material

Rotary Face

Carbon graphite resin impregnated

Hot-Pressing carbon

Silicon carbide (RBSIC)

Stationary Seat

Aluminium oxide (Ceramic)

Silicon carbide (RBSIC)

Tungsten carbide

Auxiliary Seal

Nitrile-Butadiene-Rubber (NBR)

Fluorocarbon-Rubber (Viton)

Ethylene-Propylene-Diene (EPDM)

Spring

Stainless Steel (SUS304)

Metal Parts

Stainless Steel (SUS304)

Recommended Applications

- Fresh water supply

- Building services engineering

- Waste water technology

- Food technology

- Sugar production

- Pulp and paper industry

- Oil industry

- Petrochemical industry

- Chemical industry

- Water, waste water, slurries (solids up to 5 % by weight)

- Pulp (up to 4 % otro)

- Latex

- Dairies, beverages

- Sulfide slurries

- Chemicals

- Oils

- Chemical standard pumps

- Helical screw pumps

- Stock pumps

- Circulating pumps

- Submersible pumps

- Water and waste water pumps

- Oil applications

Notes

The WMG1 can also be used as a multiple seal in tandem or in a back-to-back arrangement. Installation proposals available upon request.

Dimension adaptations for specific conditions, e. g. shaft in inches or special seat dimensions are available upon request.

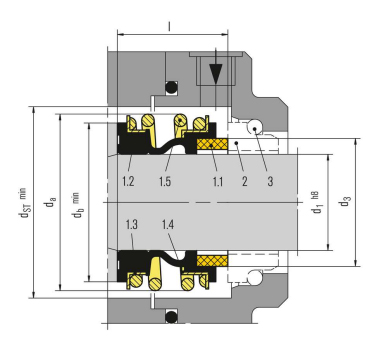

Item Part no. to DIN 24250 Description

1.1 472 Seal face

1.2 481 Bellows

1.3 484.2 L-ring (spring collar)

1.4 484.1 L-ring (spring collar)

1.5 477 Spring

2 475 Seat

3 412 O-Ring or cup rubber

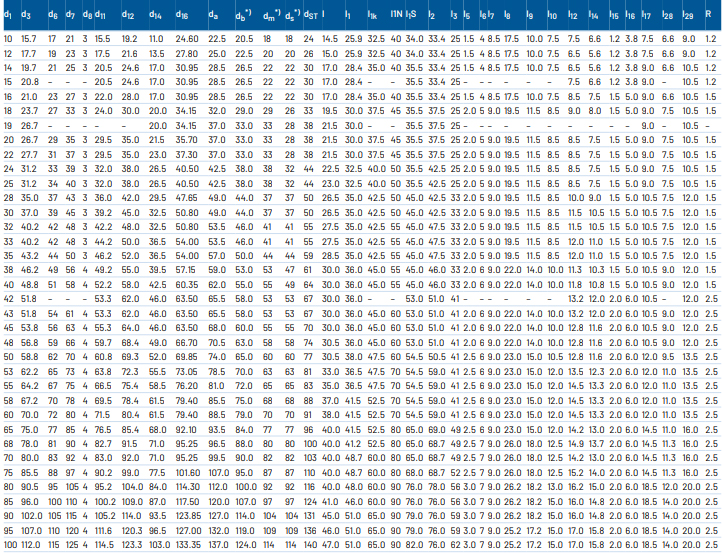

WMG1 dimension date sheet(mm)

water pump shaft seal, mechanical pump seal