We believe that long time period partnership is a result of top of the range, value added services, rich expertise and personal contact for metal bellow cartridge mechanical seal for marine industry, We have been in operation for more than 10 years. We are dedicated to quality products and consumer support. We invite you to visit our company for a personalized tour and advanced business guidance.

We believe that long time period partnership is a result of top of the range, value added services, rich expertise and personal contact for , We also have good cooperation relationships with many good manufacturers so that we can deliver almost all of auto parts and after-sales service with high quality standard,lower price level and warmly service to meet demands of customers from different fields and different area.

Features

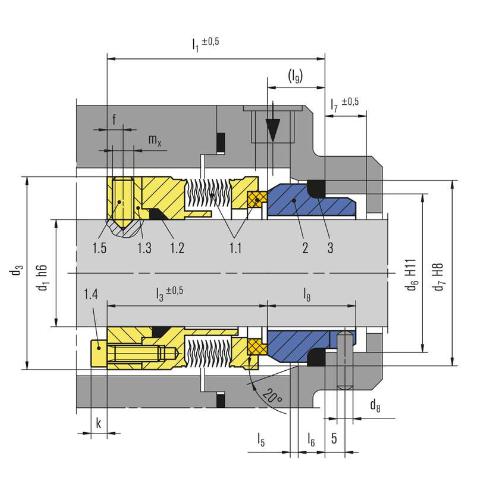

•For unstepped shafts

•Single Seal

•Balanced

•Independent of direction of rotation

•Metal bellows rotating

Advantages

•For extreme high temperature ranges

•No dynamically loaded O-Ring

•Self-cleaning effect

•Short installation length possible

•Pumping screw for highly viscous media available (dependent on direction of rotation).

Recommended applications

•Process industry

•Oil and gas industry

•Refining technology

•Petrochemical industry

•Chemical industry

•Pulp and paper industry

•Hot media

•Highly viscous media

•Pumps

•Special rotating equipment

Combination Materials

STATIONARY RING: CAR/ SIC/ TC

ROTARY RING: CAR/ SIC/ TC

SECONDARY SEAL: GRAQHITE

SPRING AND METAL PARTS: SS/ H-C

BELLOW: AM350

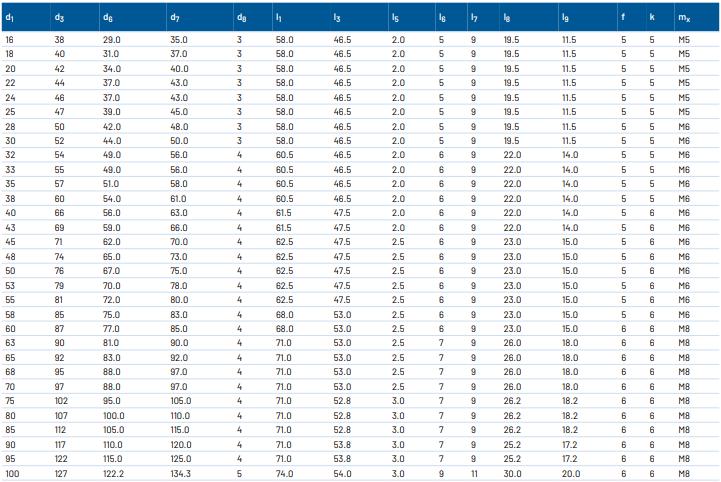

WMFWT data sheet of dimension (mm)

Advantages of metal bellow mechanical seals

Metal bellows seals have many advantages over common pusher seals. The obvious advantages include:

- No dynamic o-ring eliminating the possiblity of hang-ups or shaft wear.

- Hydraulically balanced metal bellows allow the seal to handle more pressure without heat build up.

- Self Cleaning. Centrifugal force throws solids away from the seal face – Trim design allow fit into tight seal boxes

- Even face loading

- No Springs to clog

Most often metal bellows seals are thought of as High Temperature seals. But metal bellows seals are often effective in a wide range of other seal applications. The most common of these is chemical, general water pump applications. For many years an inexpensive form of metal bellows seals have been used very successfully in the waste water / sewage industry and in the agricultural fields pumping irrigation water. These seals were generally made of a formed bellows rather than a welded bellows. Welded bellows seals are much stronger and have superior flex and recovery characteristics which are more ideal to holding seal faces together but cost more to manufacture. Welded metal bellows seals are less prone to metal fatigue .

Because metal bellows seals only require one o-ring, and because that o-ring can be made with PTFE, metal bellows seals are and excellent solution on chemical applications where Kalrez, Chemrez,Viton, FKM, Buna, Aflas or EPDM are not compatible. Unlike an ASP Type 9 seal the o-ring will not cause wear because it is not dynamic. Installation with a PTFE o-ring must be done with more attention paid to surface of the shaft condition, however PTFE encapsolated o-rings are also available in most sizes to aid in sealing irregular surfacing..

mechanical pump seal for marine industry