Our progress depends within the advanced products, fantastic talents and repeatedly strengthened technology forces for Flowserve multi-spring RO mechanical seal for marine industry, We are going to continually strive to boost our company and offer the top high quality goods with aggressive costs. Any inquiry or comment is extremely appreciated. Be sure to make contact with us freely.

Our progress depends within the advanced products, fantastic talents and repeatedly strengthened technology forces for , Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We now have won a good reputation for outstanding customer service among our overseas customers. We will continue to try the best to supply you good quality products and solutions and the best service. We’ve been looking forward to serving you.

Features

•Single Seal

•Dual Seal available upon request

•Unbalanced

•Multi-spring

•Bi-directional

•Dynamic O-ring

Recommended Applications

Pulp & Paper

Mining

Steel & Primary Metals

Food & Beverage

Corn Wet Milling & Ethanol

Other Industries

Chemicals

Basic (Organic & Inorganic)

Specialty (Fine & Consumer)

Biofuels

Pharmaceutical

Water

Water Management

Waste Water

Agriculture & Irrigation

Flood Control System

Power

Nuclear

Conventional Steam

Geothermal

Combined Cycle

Concentrated Solar Power (CSP)

Biomass & MSW

Operating ranges

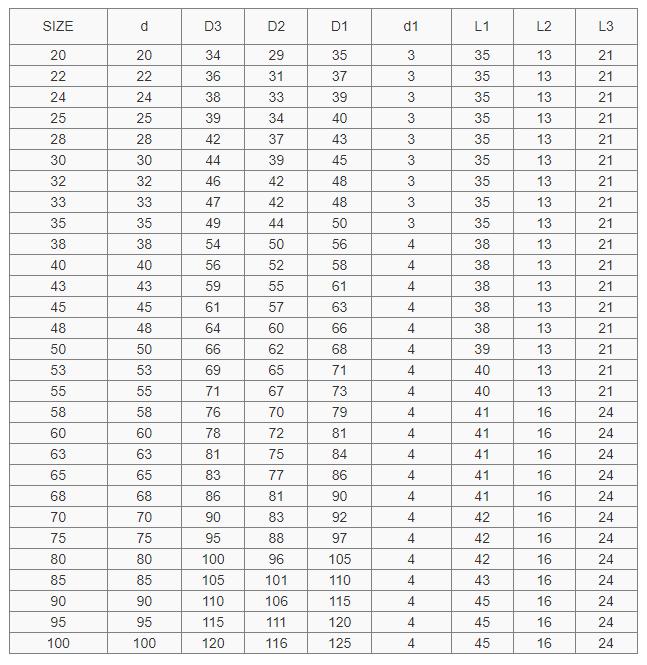

Shaft diameter: d1=20…100mm

Pressure: p=0…1.2Mpa(174psi)

Temperature: t = -20 °C …200 °C(-4°F to 392°F)

Sliding velocity: Vg≤25m/s(82ft/m)

Notes: The range of pressure, temperature and sliding velocity is depend on seals combination materials

Combination Materials

Rotary Face

Silicon carbide (RBSIC)

Tungsten carbide

Cr-Ni-Mo Sreel (SUS316)

Stationary Seat

Silicon carbide (RBSIC)

Carbon graphite resin impregnated

Auxiliary Seal

Fluorocarbon-Rubber (Viton)

Ethylene-Propylene-Diene (EPDM)

PTFE Coated VITON

PTFE T

Spring

Stainless Steel (SUS304)

Stainless Steel (SUS316)

Metal Parts

Stainless Steel (SUS304)

Stainless Steel (SUS316)

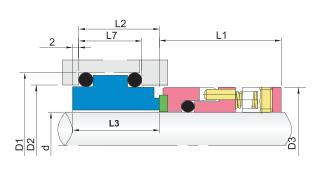

WRO data sheet of dimension (mm)

multi-spring mechanical seal for marine industry